In the era driven by the convergence of artificial intelligence and high-frequency, high-speed technologies, precision connection points that ensure accurate and stable transmission of signals and energy are becoming the key to defining the performance and reliability of high-end electronic products.

From December 3 to 5, 2025, the annual grand event of the global printed circuit board (PCB) and electronic assembly industry — the 2025 International Printed Circuit Exhibition (HKPCA Show) — was grandly held at the Shenzhen World Exhibition & Convention Center.

Themed "Quality Life · AI — PCB Business Opportunities Shine", this exhibition featured a four-hall layout for the first time, covering a total area of 80,000 square meters and gathering more than 600 industry leaders and innovative enterprises from around the world. Beyond showcasing cutting-edge technologies, this grand event clearly revealed that against the backdrop of the explosion of AI computing power and the intelligent upgrading of the industry, connectors and wiring harnesses, regarded as the "neural networks" and "energy vasculature" of electronic products, are facing profound technological changes and unprecedented value enhancement.

01 Industry Grand Event: Dual-Driven by AI and High-Frequency High-Speed Technologies, the Industry Ushered in a Value Inflection Point

As one of the most influential industry exhibitions in Asia and even the world, the HKPCA Show is undoubtedly a weather vane for the sector. Behind the unprecedented scale of this exhibition lies a concentrated industrial consensus: the widespread application of AI technology and the surge of data are propelling the PCB and the entire electronic manufacturing industry into the "era of three highs" characterized by high performance, high density, and high reliability.

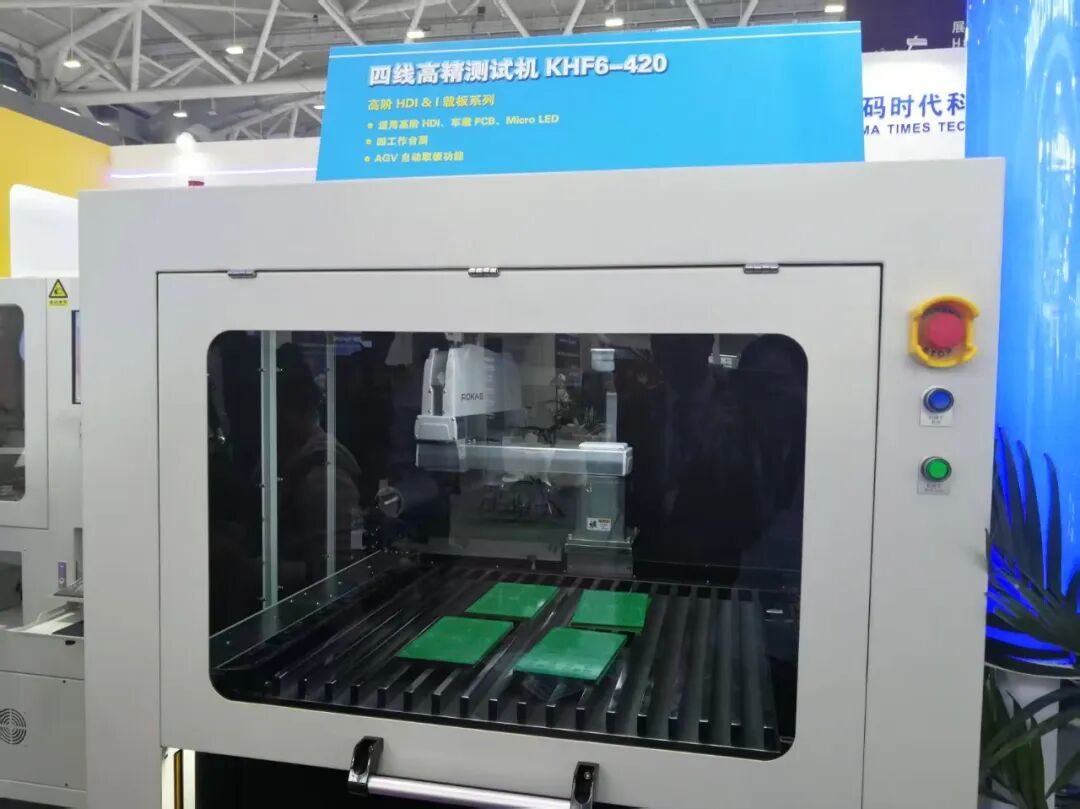

At the exhibition site, almost all cutting-edge exhibits, ranging from AI servers and intelligent automotive electronics to advanced packaging (such as IC substrates), pointed to the ultimate pursuit of signal transmission rate, integrity, and power-bearing capacity.

Industry forecasts indicate that the criteria for evaluating industrial value are undergoing fundamental changes — technological innovation and performance indicators will replace simple production capacity scale as the core basis for value pricing. This means that the strategic status of core components that provide key support for high-end applications is being redefined.

Notably, the exhibition specially added a "Precision Components and Parts Zone" this year, explicitly elevating supporting products such as connectors and precision molds to the status of key links supporting the coordinated upgrading of the industrial chain for display. This arrangement accurately reflects the urgent needs of downstream system manufacturers: in the race for ultimate performance, the failure of any single connection point may lead to bottlenecks in the entire system.

02 Trend Insight: Connectivity Technology Faces Core Challenges in the "Era of Three Highs"

The technical paths revealed by the exhibition put forward clear and stringent requirements for upstream connector and wiring harness suppliers. These challenges are also the thresholds that must be crossed for industrial upgrading.

High-speed and high-frequency transmission has become a rigid demand. The massive volume of data generated by AI training and inference requires connection channels to have extremely high transmission rates and extremely low signal loss. Whether it is server interconnection inside data centers or communication between numerous sensors and domain controllers in intelligent vehicles, connectors must address complex issues such as electromagnetic interference (EMI), impedance matching, and signal integrity to ensure the purity and smoothness of data flow.

High power density brings heat dissipation and safety challenges. With the improvement of equipment integration and the increase of power, how to transmit larger currents safely and efficiently in smaller spaces has become a key issue. Especially in the 800V high-voltage platforms of new energy vehicles and server liquid cooling solutions, connectors are faced with comprehensive tests including high voltage resistance, high temperature resistance, arc resistance, and collaborative design with heat dissipation systems.

High reliability is the cornerstone of intelligent applications. In scenarios where failures are intolerable, such as autonomous driving and industrial automation, the long-term stability and environmental adaptability (such as vibration resistance and corrosion resistance) of connection systems are the basic guarantee of product life cycles. Any minor connection failure may be amplified into a systemic risk in intelligent systems.

03 Value Resonance: Empowering the Intelligent Industrial Ecosystem with Reliable Connectivity

As a dedicated player in the field of electronic interconnection, we closely follow every technological pulse transmitted by the HKPCA Show. We deeply understand that in the process of the industry advancing towards the "era of three highs", the value of connectivity solution providers is not only to manufacture a physical interface, but also to become an important part of the reliability, high performance, and forward-looking nature of customers' products.

We are committed to transforming industrial trends into specific product development directions and technical capabilities:

For high-speed data transmission scenarios: We have developed a series of connectivity solutions optimized for high-frequency signals. Through precision terminal design, selection of low-loss dielectric materials, and comprehensive shielding structures, we aim to minimize signal attenuation and crosstalk, meeting the stringent requirements of AI servers, high-end communication equipment, and intelligent driving systems for high-speed and lossless data transmission.

To address high power and harsh environments: For fields such as new energy vehicles and industrial power supplies, our high-current connectors and high-temperature and high-voltage resistant custom wiring harnesses adopt high-performance alloy contacts and special insulating materials to ensure low energy consumption and high safety during large-current transmission. The product design fully considers thermal management and can adapt to the challenges of wide temperature ranges and complex working conditions.

To provide high-density integration solutions: In line with the trend of miniaturization and modularization of electronic products, we offer miniaturized, high-pin-count connectors and highly customized precision wiring harnesses. Our engineering team can deeply participate in the product design stage of customers, providing integrated support from space optimization and electromagnetic compatibility (EMC) design to manufacturability analysis, helping customers maximize functions in limited spaces.

04 Moving Forward Together: Becoming Your Trusted Interconnection Partner

The successful holding of HKPCA Show 2025 not only presented a technological feast, but also built a platform for global industrial collaborative innovation. It enlightens us that future competition is the competition between industrial chain ecosystems. Only through close collaboration and synchronous innovation between upstream and downstream can we jointly seize the huge business opportunities empowered by AI.

We always uphold the philosophy of "Innovation, Reliability, Collaboration". Our goal is not only to provide high-quality electronic connectors, LED connectors, and custom wiring harnesses, but also to become a reliable partner for you on the road of R&D and innovation. By deeply understanding your application scenarios and future plans, we will seamlessly integrate our expertise in connectivity technology into your product blueprint.

From the convenient interconnection of smart homes, to the powerful power of new energy vehicles, and then to the surging computing power transmission of data centers, reliable connectivity is everywhere. We look forward to conducting dialogues with electronic manufacturing enterprises, solution design companies, and brand owners around the world, and jointly exploring how to make the next generation of intelligent products more competitive through more optimized and forward-looking connectivity solutions.

Products Recommendations:

| Product Category | Part Number | Altemative | Product Image |

| Wire-to-Board Connector | |||

| Board-to-Board Connector | BD2002 | ||

| Wire-to-Wire Connector | C1251 | ||

| FPC Series | F0502 | ||

| Through Hole Reflow Series |