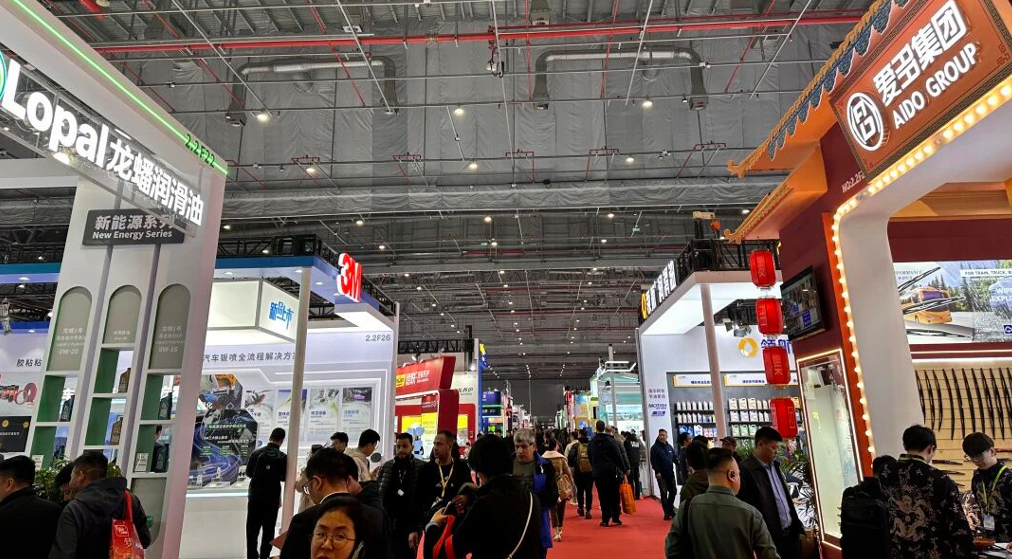

As the pulse of the global automotive industry beats strongly at the National Exhibition and Convention Center (Shanghai), an industry grand event themed "Innovation, Integration, Sustainable Development" paints a clear picture of the future for the world. From November 26 to 29, 2025, the 22nd Shanghai International Auto Parts, Maintenance, Repair and Diagnostic Equipment and Services Exhibition (Automechanika Shanghai) was held on an unprecedented scale. For the first time, the exhibition utilized all 15 exhibition halls, covering a record 383,000 square meters. It attracted 7,465 enterprises from 44 countries and regions, and professional visitors from nearly 160 countries and regions. The active participation of 261 professional buyer delegations testified to the unprecedented demand for collaborative development and business cooperation in the global automotive industry.

As one of the top three auto parts exhibitions globally and the largest in Asia, Automechanika Shanghai not only showcased expanded scale but also focused direction. Exhibition data indicated that the new energy and intelligent connectivity sector emerged as the absolute core, with exhibition space increasing by 50% year-on-year and over 40% of exhibitors presenting related solutions. From the three-electric system (battery, motor, electronic control), smart cockpit, and ADAS to intelligent chassis, every innovative cell in the industrial chain is reshaping the definition of "automobile." Notably, new energy components, electronic control parts, and intelligent driving perception components became the focus of inquiries, clearly revealing the irreversible trend of the automotive industry towards "electronic and electrical architecture upgrading." In this grand transformation, connectors and wiring harnesses—acting as the "neural network" and "energy vasculature" of automobiles—directly determine the vehicle's performance, safety limits, and user experience through their technical capabilities.

Trend Focus: Technology Iteration Directions, Defining New Connectivity Standards

The event clearly outlined four core directions for the iteration of automotive connectivity technology, each posing a severe test for suppliers' comprehensive capabilities:

High Voltage and High Reliability: With the popularization of 800V high-voltage platforms, connectivity systems must withstand the continuous impact of higher voltage and larger current. High-voltage connectors need excellent voltage resistance, arc resistance, and stability within a wide temperature range of -40℃~125℃ and under harsh vibrations—serving as the cornerstone for the safe operation of battery packs and electric drive systems.

High Speed and High Fidelity: Intelligent driving relies on real-time, lossless transmission of massive data. Connectors must support stable interaction of GHz-level high-speed signals in limited spaces and adopt precision shielding structures to reduce electromagnetic interference (EMI), ensuring the accuracy of perception data from millimeter-wave radars, cameras, and other devices.

Lightweight and Material Innovation: "Weight reduction for efficiency" has become an industry consensus, driving the application of material technologies such as "aluminum replacing copper." By optimizing wiring harness design and using lightweight materials, vehicle cost reduction, energy conservation, and emission reduction are achieved while maintaining performance.

Integration and Deep Customization: To adapt to the spatial layout and functional integration of different vehicle models, the demand for modular design and full-process customized services is increasingly prominent. This requires suppliers to deeply participate in customer R&D and provide personalized wiring harness solutions from concept to mass production.

Value Resonance: JKUN's Precision Solutions, Addressing Industry Challenges

With years of experience in the electronic connectivity field, Wenzhou JKUN Connector Co., Ltd.'s technical layout is highly aligned with industrial trends. We are committed to providing robust and reliable solutions for global customers in the smart electrification era through innovative connectivity technology:

High-Voltage Connectivity Solutions for New Energy Vehicles: Targeting high-voltage and high-safety requirements, JKUN's industrial-grade high-voltage connectors adopt special alloy contacts and high-performance insulating materials, meeting the demands of 800V and above platforms. Passing rigorous vibration and impact tests, the products feature an IP rating of IP67 or higher, providing stable and reliable"energy vasculature" for battery management systems (BMS), motor controllers, and charging-swapping equipment.

High-Speed Data Connectivity Technology for Intelligent Connectivity: For intelligent driving and cockpits, we offer signal connectors and fully shielded wiring harness assemblies supporting high-speed, low-loss transmission. Their precision design effectively ensures signal integrity for ADAS systems and in-vehicle entertainment systems. Meanwhile, compact LED connectors provide stable connectivity for in-vehicle ambient lighting and display systems, enhancing the immersive smart cockpit experience.

Lightweight and Customized Wiring Harness Integration Services: We provide full-cycle customized wiring harness solutions throughout product development. From cable selection, routing planning, and electromagnetic compatibility (EMC) design to modular assembly, our engineering team collaborates closely with customers. We can adopt environmentally friendly lightweight materials and low-smoke zero-halogen(LSZH) processes as needed, improving assembly efficiency, reducing failure rates, and helping vehicles achieve lightweighting, energy conservation, and emission reduction goals.

Backed by solid technical accumulation, our products have obtained international authoritative certifications such as UL, CUL, and CE, with a plug-in lifespan exceeding 2,000 cycles and excellent stability under complex working conditions. Today, JKUN's solutions are widely applied in new energy vehicles, intelligent connected vehicles, and traditional fuel vehicles. Leveraging cross-domain synergy with our technical experience in consumer electronics and smart homes, we provide reliable and cost-effective product support for global customers, especially in emerging markets such as Southeast Asia and the Middle East.

Creating the Future Together: Becoming a Trusted "Connectivity Partner" in the Global Automotive Industry Chain

The success of Automechanika Shanghai 2025 not only demonstrates the vigorous vitality of China's automotive industry chain but also signals the dawn of a new era of cross-domain integration and collaborative innovation. Facing the profound transformation of the automotive industry and broad opportunities in the global market, Wenzhou JKUN Connector Co., Ltd. will continue to uphold the core values of "Innovation, Quality, Service."

We will continuously increase R&D investment, deepen key technologies such as high-voltage connectivity, high-speed signal transmission, and lightweight design, and constantly optimize product performance and customized service capabilities. We look forward to collaborating with global automakers, Tier 1 suppliers, and technology partners to explore how to inject stronger competitiveness and reliability into the next generation of smart electric vehicles through more optimized connectivity solutions.

Driving industrial transformation and connecting a green future, JKUN is ready to be your trusted global connectivity partner with professionalism and reliability, jointly building a smarter, safer, and more sustainable mobility ecosystem.

Products Recommendations:

| Product Category | Part Number | Altemative | Product Image |

| Automotive Connector | |||

| QA2505 | |||

| Electronic Connector | |||

| A10013 | |||

| A5701 | |||

| F1001 |