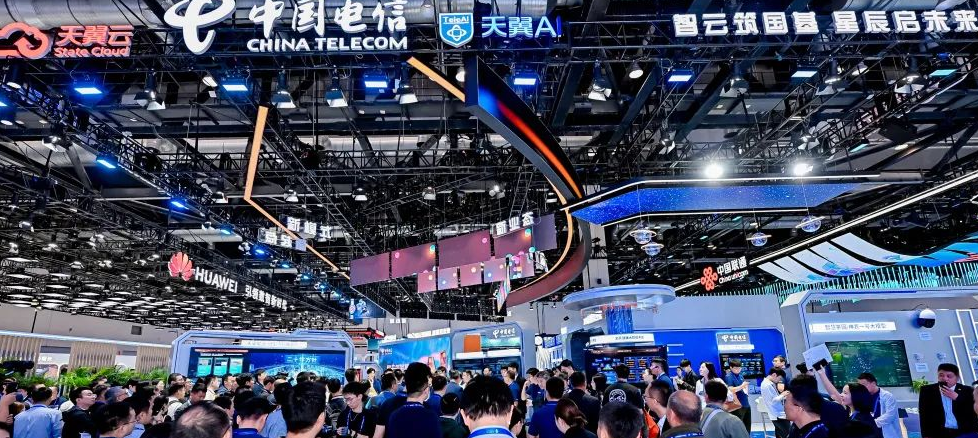

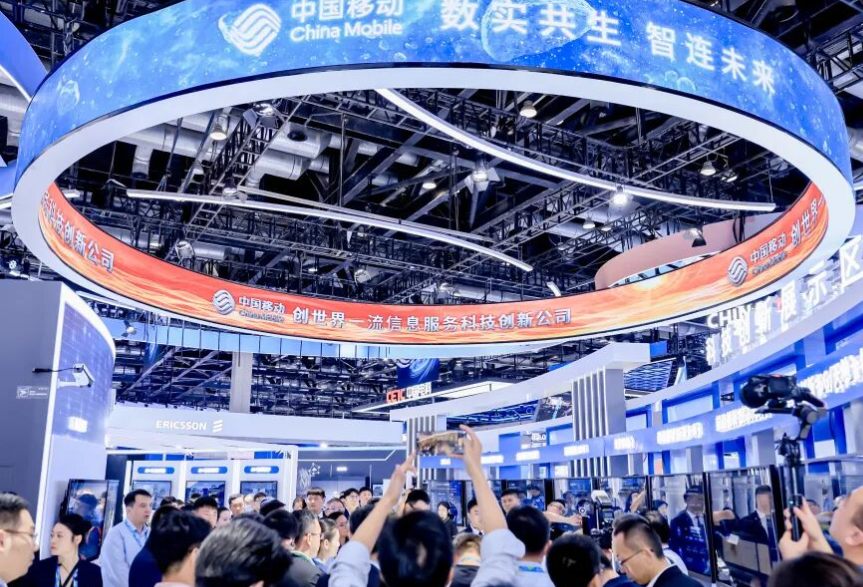

The 2025 China International Information and Communications Exhibition recently concluded at the China National Convention Center in Beijing. With the theme "Integration of Digital and Real Economies as a New Engine, Intelligent Empowerment for Future Growth," this exhibition showcased cutting-edge technologies such as 5G-Advanced (5G-A), 6G, and low-altitude intelligent networks. Behind the implementation of these technologies lies a group of "unsung enablers"—high-quality connectors that are constantly evolving. From 5G-A networks with millisecond-level latency to 6G holographic communication that blurs the line between virtual and physical reality, and even low-altitude communication devices capable of withstanding force 12 winds, every leap in communication technology brings new demands and opportunities to the connector industry.

I. Leaps in Communication Technology Propel Upgraded Connector Demands

One of the most striking takeaways from the exhibition was that communication technology is evolving from "functional usability" to "high performance and durability," driving corresponding upgrades in connector requirements.The on-site demonstration of Huawei’s 5G-A network drew significant attention: its uplink speed is several times faster than that of standard 5G, with latency reduced to the millisecond level—scenarios such as remote-controlled robotic arms and high-definition video transmission showed almost no delay. To date, 5G-A networks have been deployed in 300 cities across China, with over 30 million package subscribers. Every high-speed data interface in these base stations and end devices relies on high-frequency connectors; without them, even the fastest speeds cannot be transmitted smoothly.

ZTE’s 6G holographic communication was equally impressive: technicians wearing XR headsets could engage in "face-to-face" conversations with virtual digital humans thousands of miles away, with real-time synchronization of even subtle facial expressions. This "time-transcending" experience places extremely strict demands on connection stability and bandwidth—traditional connectors are unable to meet these needs, requiring new products capable of supporting ultra-large bandwidth and ultra-low loss.

The low-altitude economy emerged as a new highlight at the exhibition. China Tower displayed its disaster-resistant super base stations, which can withstand magnitude 8 earthquakes and force 12 winds; Linzhou Technology unveiled its near-space airships, capable of providing mobile phone coverage over a 60-kilometer radius. However, the complex high-altitude environment—characterized by vibration, temperature fluctuations, and humidity changes—requires connectors in these devices to be corrosion-resistant, high-temperature-resistant, and capable of maintaining stable contact even under strong vibrations. Without reliable connectors, applications like drone logistics and air taxis would remain unfeasible.

It is clear that these breakthroughs in communication technology are pushing the connector industry toward "faster, more stable, and smaller" development—high frequency, high speed, high reliability, and miniaturization have become core keywords for industry upgrading.

II. Deepening Integration of Digital and Real Economies Expands the Connector Market

5G is no longer just a tool for streaming videos; it has now been integrated into 86 major categories of the national economy and is accelerating its penetration into core production links. As of the end of August 2025, the total number of 5G base stations in China reached 4.646 million, with 1.154 billion 5G mobile phone users. Behind these figures lies massive demand for connectors: every link—from signal transmission modules in base stations and motherboard interfaces in mobile phones to switches in data transmission links—depends on connectors.

The improvement of computing infrastructure has further boosted the connector market. China Telecom announced at the exhibition that it has achieved full coverage of heterogeneous computing power, including general computing, intelligent computing, supercomputing, and quantum computing; China Mobile has also built 13 national and regional intelligent computing centers. In these computing centers, high-density, low-loss backplane connectors enable high-speed data interaction between servers and storage devices—a large-scale intelligent computing center can require hundreds of thousands or even millions of connectors.

Connectors are also playing an increasingly critical role in "AI + manufacturing" scenarios. A car factory that adopted 5G-A + AI for quality inspection saw efficiency increase by 40%. This achievement relied on high-reliability connectors that enabled real-time networking of production line equipment, allowing data to be quickly transmitted to AI models for analysis. Liang Ce, Director of Huawei’s China Operator Marketing Department, put it plainly at the exhibition: "5G-A is not a simple iteration from 4G to 5G, but a ‘network necessity’ in the AI era"—and behind this "necessity" lies a demand for high-quality connections.

III. New Scenarios Spur Technological Innovation: Connectors Must Adapt to Application Needs

Different communication scenarios impose distinct requirements on connectors. Several key scenarios at the exhibition highlighted the "hard indicators" for connectors:

Low-Altitude Intelligent Networks: Durability is Essential

The sand table in the low-altitude economy section was filled with models of drone logistics and air taxis, indicating that low-altitude communication has moved from concept to practical application. However, the high-altitude environment is far more complex than the ground: vibration during drone flight, low temperatures and humidity changes at high altitudes, and even occasional salt spray (in coastal areas) can all affect connector performance. Thus, connectors for these scenarios must pass three tests—vibration resistance, high-temperature resistance, and corrosion resistance—to avoid equipment failures in the air.

6G Holographic Communication: High-Speed Transmission is a Must

ZTE’s 6G immersive digital human technology is blurring the line between virtual and reality, but real-time holographic communication requires sufficient data transmission speed and stability. Future 6G will use millimeter-wave bands, which offer larger bandwidth and faster speeds—but millimeter-wave transmission demands higher precision from connectors: even minor poor contact can cause signal attenuation. Therefore, connectors must evolve toward "millimeter-wave compatibility and larger bandwidth support" to enable 6G holographic applications.

Smart Manufacturing: Durability and Precision are Dual Requirements

China Telecom’s industrial quality inspection model at the exhibition achieved real-time linkage with production line equipment, significantly improving defect identification accuracy; China Mobile’s 5G-A smart mine sand table demonstrated autonomous obstacle avoidance by unmanned mining trucks in a simulated mine environment. In these industrial scenarios, equipment operates for long periods in dusty, vibrating, and temperature-fluctuating environments. Connectors must be both durable (with a long plug-in lifespan) and precise (with low contact resistance to prevent data transmission errors)—even a one-minute production line outage can result in substantial losses.

IV. Seizing Opportunities to Serve as a Reliable Backbone for Communication Technology

As the communication industry evolves rapidly, connector enterprises must not only keep pace but also layout ahead. For us, we are focusing on three key directions:

First, tackling high-frequency and high-speed technologies. 5G-A is already pushing for higher transmission speeds, and future 6G will adopt millimeter-wave bands. We are developing dedicated connectors for millimeter-wave frequencies; our connectors for 5G-A base stations have already achieved a 30% increase in transmission speed, and our next goal is to overcome technical bottlenecks for 6G scenarios.

Second, enhancing reliability in complex environments. Scenarios such as the low-altitude economy and industrial internet demand high durability from connectors. We are optimizing materials and structures—using high-temperature and low-temperature resistant special plastics for housings, gold-plated contacts to reduce contact resistance, and structural designs to enhance vibration resistance—ensuring stable performance even in harsh conditions.

Third, advancing miniaturization and high density. Communication devices are becoming increasingly compact (e.g., drone communication modules and small base stations), leaving less space for connectors. We are developing high-density connectors with "small size and multiple interfaces," enabling multi-link connections in limited spaces.

Currently, we have launched a series of connector solutions for 5G base stations, data centers, and industrial internet. For example, our high-frequency connectors for 5G base stations are already in mass production for major domestic operators’ base station projects; our high-reliability connectors for industrial scenarios have been deployed in automotive and mining industries.

Liu Kang, President of Huawei’s ICT Marketing and Solution Sales Department, predicted at the exhibition: "By 2030, the number of Agents will exceed that of traditional Apps, and everyone will have a dedicated intelligent assistant." When that time comes, massive smart terminals will need to be connected to networks. As the "neural endings" of information infrastructure, connectors directly determine the performance and stability of the entire communication system. For us, only by mastering core technologies and delivering high-reliability, adaptable connector solutions can we gain a firm foothold in the wave of the digital economy and truly serve as a reliable backbone for the development of communication technology.