In recent years, the wave of the "self-pleasure economy" and "personal care upgrading" has swept the globe. Consumers' demands for personal care appliances have long gone beyond basic functions — evolving from quick hair drying to intelligent hair care, and from bulky bodies to lightweight designs. This small hair dryer has become a new carrier integrating technology and aesthetics.

Driven by this trend, the global high-end hair dryer market has witnessed explosive growth: According to the latest 2024 report from HengCe Consulting, the global luxury hair dryer market sales have reached 2.931 billion US dollars. As a core growth engine, China's cumulative retail sales of hair dryers exceeded 12.7 billion RMB in the first three quarters of 2024, a year-on-year increase of 28.4%. Among them, high-end models priced above 800 RMB contributed nearly half of the sales, becoming the main driver of market growth. Behind all this is a vivid reflection of consumers' life proposition — "Every strand of hair deserves meticulous care" — turning from a concept into reality.

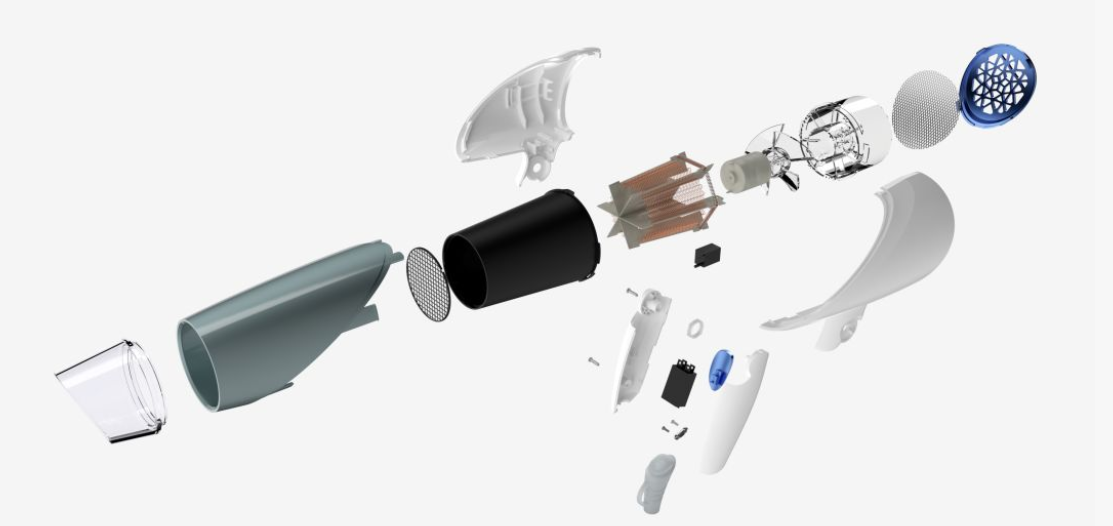

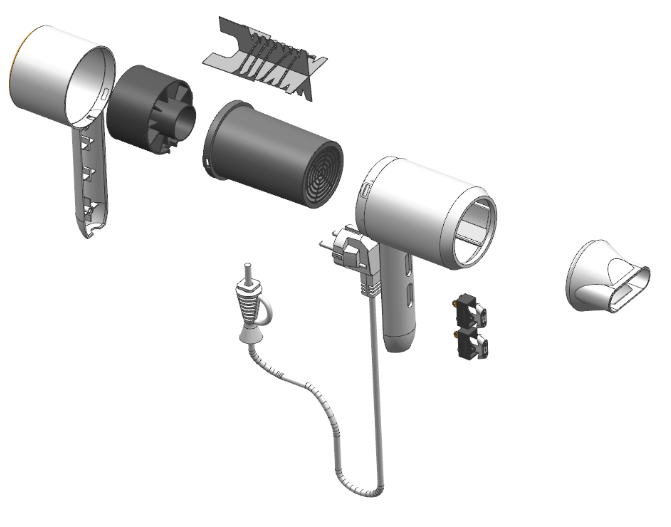

In this "hair revolution", hair dryers are no longer just simple "air-blowing tools". The collaborative operation of precision components such as 110,000 revolutions per minute high-speed brushless motors, intelligent constant temperature chips with 100 temperature monitoring cycles per second, hair care modules that release tens of millions of negative ions, and magnetic replaceable nozzles has enabled household hair dryers to deliver salon-like care effects. But few people notice: when the motor operates at high speed generating high-frequency vibration, the temperature control chip transmits data in real time, and the LED display clearly shows gears, what guarantees the "zero-error" collaboration of these functions behind the scenes?

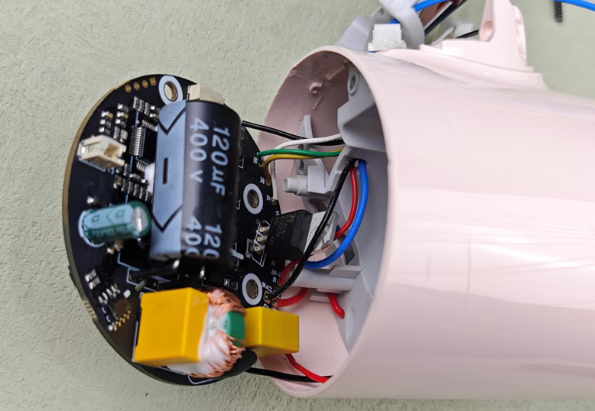

The answer lies in those invisible yet indispensable details — precision connectors and customized wiring harnesses.

The interior of a high-end hair dryer is a "miniature yet complex" electronic system: the motor requires stable current supply, the temperature control sensor needs to transmit temperature data in milliseconds, and the LED indicators and switch circuits must maintain reliable connections at all times. More importantly, hair dryers generate continuous high temperatures during operation, and high-speed motors bring high-frequency vibration. This places extremely high requirements on the high temperature resistance and vibration resistance of connecting components — any loose connection or signal interruption will not only reduce hair care effectiveness but may even cause safety hazards. It can be said that the quality of connectors and wiring harnesses directly determines the "stability ceiling" of high-end hair dryers.

— And this is the professional field that Wenzhou JKUN Connector Co., Ltd. has dedicated to for 12 years.

We deeply understand that a "easy-to-use and durable" high-end hair dryer cannot do without "invisible excellent connections". Targeting the stringent requirements of high-end personal care appliances, JKUN has developed three core customized solutions:

Miniaturized electronic connectors: Adapt to the compact internal space of hair dryers, realizing zero-latency signal transmission between the main board, motor, and temperature control sensor. Even in high-frequency vibration environments, they ensure stable flow of data and current;

High-temperature resistant LED connectors: Specifically designed to cope with high-temperature scenarios during hair dryer operation, providing long-lasting and reliable connections for indicators and displays. Their service life is more than 30% longer than ordinary connectors, avoiding problems such as "non-illuminating lights or incomplete display" after long-term use;

Customized wiring harness solutions: Optimize wiring design according to the internal layout of different models. They not only reduce the impact of electromagnetic interference on temperature control and negative ion modules but also improve overall energy efficiency, making the collaboration between the motor and hair care functions more efficient.

Today, JKUN's connection solutions have been widely applied in the high-end hair dryer product lines of many well-known domestic and foreign personal care brands — from the power supply interfaces supporting 110,000-rpm brushless motors to the sensor connections ensuring intelligent constant temperature. With millimeter-level precision manufacturing, we help customers create more stable, safer, and consumer-preferred products.

From the delicate care of hair strands to the stable connection of chips, the "evolution path" of high-end hair dryers is also the practice path of JKUN's "empowering product upgrading with reliable connections". As personal care appliances continue to iterate, Wenzhou JKUN is willing to leverage its 12 years of experience in connector and wiring harness R&D to become your most trustworthy partner — whether for high-end hair dryers, smart beauty devices, or other consumer electronics fields. We can provide customized, high-reliability connection solutions to make technology seamlessly connect to wonderful experiences.

Wenzhou JKUN Connector Co., Ltd. — Specializing in connector and wiring harness solutions for 12 years, serving customers in smart home, consumer electronics, new energy vehicles and other fields, guarding every "reliable connection" with precision manufacturing.

Products Recommendations:

| Industry Common Names | Part Number | Altemative | Product Image |

| ZH1.5 | |||

| GH1.25 | |||

| SH1.0 | |||