Within precision packaging lies the pulse of the intelligent world; in micro connectors flows the blood of modern technology.

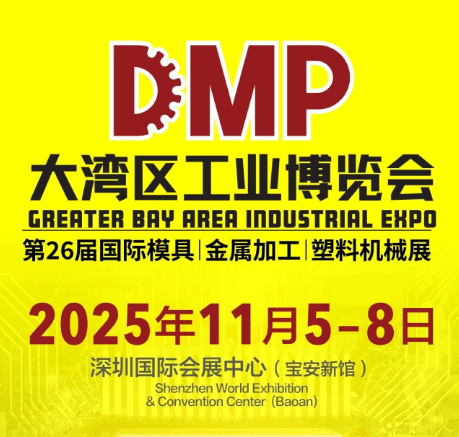

In November, Shenzhen witnesses a dual surge in industrial vitality and urban energy. The 2025 DMP Greater Bay Area Industrial Expo (Shenzhen World Exhibition & Convention Center, Nov. 5-8) is in full swing. This 26-year-old industrial gala, covering 180,000 square meters, gathers over 2,000 top global exhibitors and more than 150,000 professional visitors. It showcases cutting-edge technologies such as new energy vehicles (NEVs), smart equipment, and industrial robots, clearly mapping the accelerated iteration trajectory of manufacturing toward intelligentization, greenization, and efficiency.

01 Exhibition Insight: DMP Greater Bay Area Industrial Expo as an Industry Trend Bellwether

As a highly influential industrial flagship exhibition in Asia, the DMP Greater Bay Area Industrial Expo has long been a crucial window to insight into the future of the industry. This year’s event features core pavilions including "Automotive Manufacturing & Components" and "Smart Equipment & Industrial Internet", fully covering the entire industrial chain’s innovative achievements from core components to smart terminals. The three major trends it releases are highly synchronized with the development of the connector industry.

According to data from the China Electronic Components Association (CECA), the global connector market size is expected to exceed 95 billion US dollars in 2025, with NEVs and consumer electronics contributing over 60% of the growth. In the exhibition’s NEV pavilion, power batteries and electric drive systems are the focal points, and the industry’s demand for efficiency and stability of connection components continues to upgrade—this coincides with JKUN’s long-term technical development direction.

The consumer electronics and smart home sector is equally brilliant. Whole-house smart solutions displayed by enterprises such as Gree and Midea confirm the forecast released by IDC: global smart home device shipments will reach 1.9 billion units in 2025. Miniaturization and high transmission rates have become core demands for connectors, providing broad space for innovation in segmented fields.

02 Trend Connection: Connectors – The "Core Hub" of the Intelligent Era

No matter how complex their functions are, the various high-tech devices at the exhibition share a common foundation: reliable internal and external connections. Just as the nervous system supports human operation, connectors and wire harnesses assume the key mission of signal transmission and energy delivery in smart devices, and their performance directly affects the experience and lifespan of terminal products.

In the NEV field, with the popularization of 5C ultra-fast charging technology, connection systems need to adapt to higher energy transmission efficiency. In the next-generation electric vehicles displayed at the exhibition, high-voltage connection components and BMS (Battery Management System) collection harnesses have become core accessories that must meet stringent operating conditions. JKUN’s related products, developed through in-depth research, are gradually achieving compatibility with the technical standards of mainstream automakers.

In the smart home track, the scenario-based application of products such as LED lighting and smart security places higher requirements on the compatibility and adaptability of connectors. JKUN’s LED connector series, with its anti-environmental interference characteristics, has been widely used in various smart terminals, silently ensuring stable device operation.

03 Technical Strength: JKUN’s "Way of Connection"

As a high-tech enterprise specializing in the R&D, design, production, and sales of connectors, WENZHOU JKUN CONNECTOR CO.,LTD. has built differentiated competitive advantages in the connector field through years of technical accumulation, providing key connection support for multiple industries.

Intelligent Manufacturing and Large-Scale Production Capacity

The company has introduced over 700 sets of advanced automated production, testing, and packaging equipment from home and abroad, forming a large-scale production capacity of 3 billion sets (pieces) per year, which can efficiently meet customers' diverse delivery needs. JKUN’s independently developed automated assembly technology has obtained national patent certification, greatly improving product consistency and production efficiency.

Comprehensive Quality System Assurance

JKUN has passed international management system certifications including ISO9001, ISO14001, and IATF16949, and has accumulated more than 100 patents. Its products have successfully passed authoritative tests such as UL, CUL, and CE. These certifications are not only endorsements of technical strength but also "passports" for products to enter the global market, eliminating customers' worries about international market access.

Continuously Iterative R&D Capability

The company has built an advanced product laboratory with full-performance testing capabilities, accumulating invention patents, utility model patents, and software copyrights totaling over 100. By closely following industry technical trends, JKUN achieves in-depth adaptation of products to downstream application scenarios, providing customers with more forward-looking connection solutions.

04 Application Scenarios: "Precision Connection Solutions" for Diverse Fields

Relying on core technologies and customization capabilities, JKUN’s products have been widely used in diverse fields such as NEVs, consumer electronics, smart homes, and industrial automation, forming a solution matrix covering multiple scenarios.

In the NEV field, it provides connection components and battery connectors to meet the stable operation needs of vehicle core systems. In the consumer electronics and smart home fields, miniaturized connectors and high-speed transmission wire harnesses adapt to the technical requirements of smart wearables and high-definition audio-visual equipment. In industrial automation scenarios, high-quality connectors and signal transmission wire harnesses ensure the reliable operation of production lines.

From the cutting-edge displays at the DMP Greater Bay Area Industrial Expo to terminal applications around the world, although small in size, connectors have become indispensable core components of the intelligent era. Like invisible bridges, they link technological innovation with industrial implementation, driving the continuous upgrading of manufacturing.

WENZHOU JKUN CONNECTOR CO.,LTD. is a devoted practitioner in this critical field. Adhering to the core of "high performance and high reliability", we are committed to providing precise connection solutions for global customers, empowering the intelligent era with technical strength, and moving towards a future of win-win through intelligent manufacturing with partners.

Products Recommendations:

| Product Category | Part Number | Altemative | Product Image |

| Automotive Connector | QA20012 | ||

| QA2541 | |||

| QC2508 | |||

| Electronic Connector | |||

| F05010AWR | |||

| LED Connector | L020A-Y | ||

| L1501AFV |