In some places, such as the south, the rainy season is longer and the air is relatively humid. So when choosing an LED connector, everyone will consider the waterproof and moisture-proof function of the LED connector, so how to choose a good LED waterproof connector? Where to start? Below we will introduce in detail, there are more and more types of LED waterproof connectors on the market, but the quality is uneven, so when we hang LED waterproof connectors, we generally consider from the following aspects:

First, first, meet the relevant electrical, installation, connection, insulation, protection and other technical standards, which is the basis for selection.

Second, we should not only look at the standard, but should go beyond the standard and pay attention to the situation encountered in practical application.

Because some of the standards selected for the design and production of LED industry connectors are actually borrowed from other industries, because the industry application time is relatively short, many provisions do not meet and meet the requirements of the rapid changes in the LED industry, such as the assessment of aging resistance materials, but in general, it is in line with the use of outdoor engineering, but how to define, is to see UL yellow card or testing prevails, the life of outdoor engineering use is based on the commercial contract of the project manufacturer or to a "technical service life" that everyone can recognize, which directly affects the selection and design of product materials, and also causes LED Connector materials vary for a variety of reasons.

In addition, the requirements of individual standard clauses are still relatively low, that is to say, the quality threshold is very low, resulting in a variety of family workshops can be produced at will, some test standards are tested in the "standard static environment", often after engineering accidents, to retest the connector found that according to the standard or qualified, why? Because the laboratory tests have selected standard clauses and standard environments, and the environment of the application site is very different, such as the cable fixing head of the M16 at the end of the connector on the cable grip and anti-torque requirements, the standard only says that the tensile force reaches 80N, The torque value is greater than 0.45N.m but the connector may have artificial strong pulling and twisting in actual use, so that the actual data may be far from the standard value, and this force is maintained between the two connectors for a long time, after a long time of outdoor use. Often ends up disconnecting the connector due to lack of water resistance or poor contact.

Third, look at the production quality control system of the connector factory.

Connector companies to do a good pair of connectors to provide testing is very easy, you can also get a good test score, but when you get to the factory, you will find that there is no inspection standard for raw materials, there is no necessary test link for finished products, there is no program for repairing and testing unqualified products, etc., which affects the quality of the whole package of the product, that is to say, it is not 100% qualified, good quality system control is even the most important reference factor for lamp manufacturers to choose connector manufacturers, otherwise it will be "lost because of small". In general, enterprises with large production scale and technical testing equipment have a higher level of product quality control and stability.

Fourth, look at the structural principle design, structural design is very important.

If the design of waterproof, connection and other principles is more advanced, it is already superior, if you choose the outdated structural principle design, even if the quality control in the manufacturing process is very good, but often in reliability, outdoor long-term weather resistance and other aspects are not as reliable as the innovative generation of products.

Fifth, look at the tolerance size control accuracy of the assembly.

Because the connector often involves connection, waterproof, male and female contact with the cooperation, etc., need to have high precision requirements for the size, high-end and low-end connectors at a glance almost the shape, structure, etc. are not the same as the high and low, but how do you spend some time, with calipers carefully measure the size of the multi-pair connector will find that the quality of the poor fit size changes greatly, that is, the stability of the connection is not guaranteed, Poor consistency of batch products.

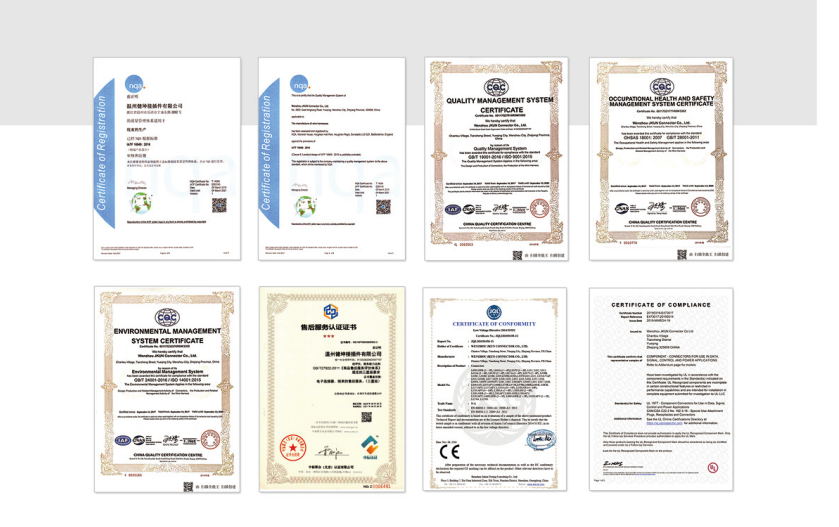

Wenzhou JKUN Connector Co., Ltd, specializing in designing, manufacturing LED connector for more than 10years,Advanced experimental equipment and strict experimental process ensure the factory quality of products.Fully automated production process and strict manual inspection links ensure the qualified rate of products.The company has got the international management system certification of ISO9001, ISO14001, OHSAS18001, IATF16949 and obtained the international authoritative certificates such as UL, CUL, CE.

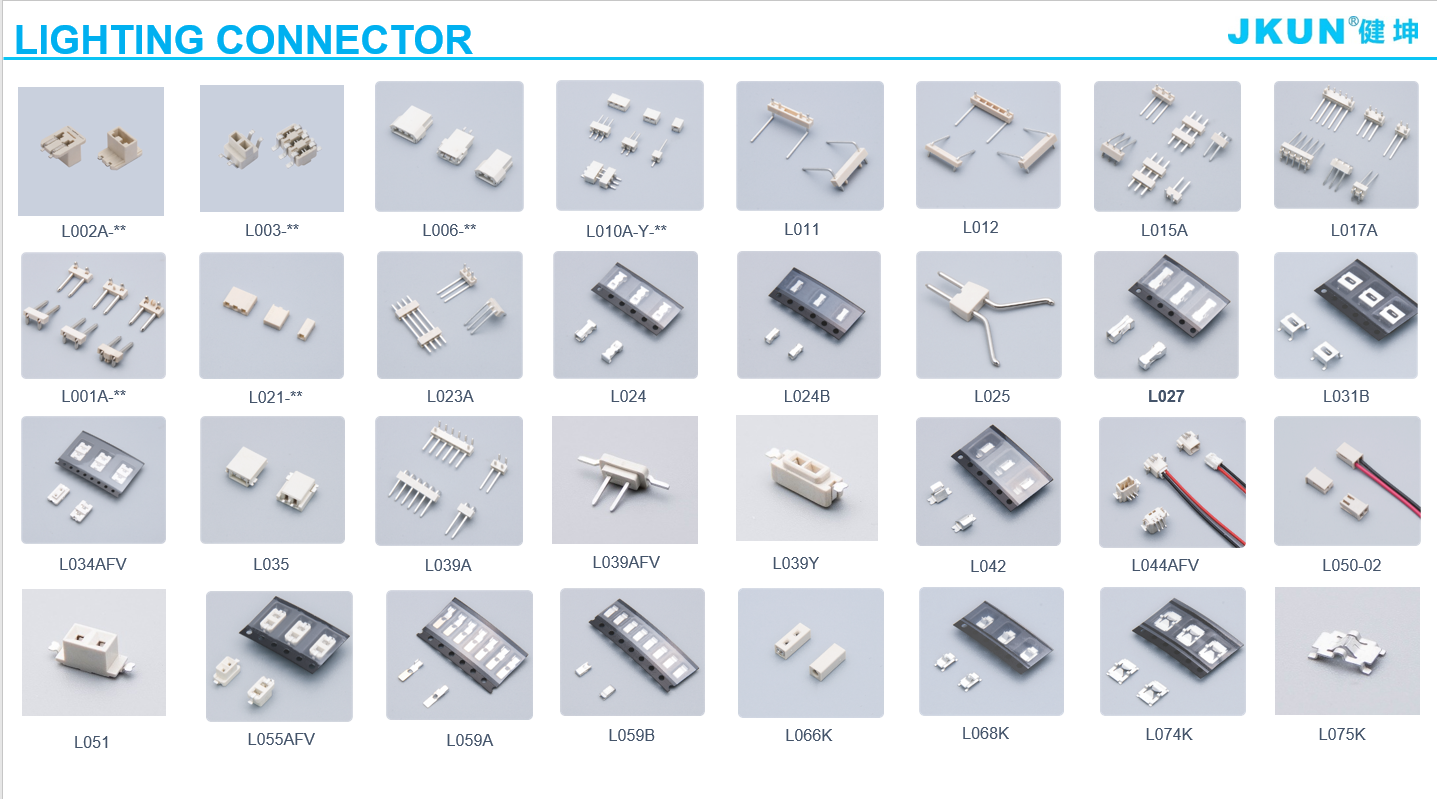

LED connect suggest: