Technological innovation is quietly reshaping lighting methods, and reliable connectivity is the foundation of it all

With the rapid development of IoT and smart home technologies, LED intelligent lighting has evolved from simple illumination functions to become core components of the smart home ecosystem. In this technological transformation, connectors, terminals, and wire harnesses, though seemingly small, play a crucial role as indispensable " pillars" of smart lighting.

01 The Smart Lighting Era: New Challenges for Connectivity Technology

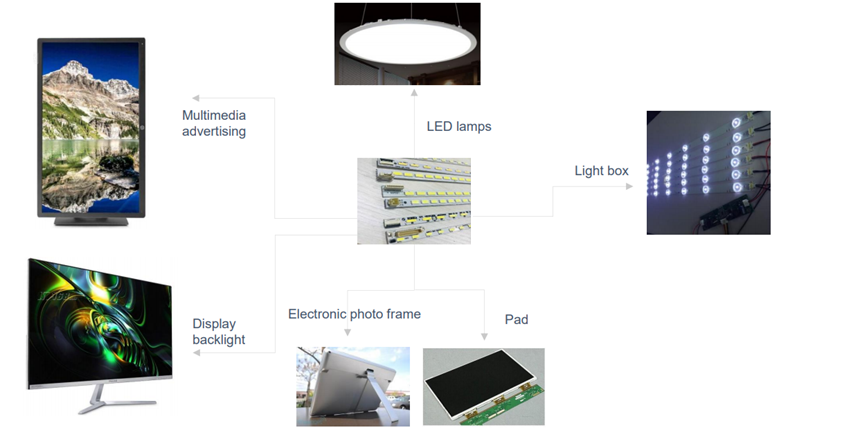

The LED lighting market is experiencing unprecedented growth and technological transformation. Smart bulbs, LED strips, outdoor smart lighting, and other products are no longer just lighting tools but also sensing nodes and control terminals in smart home systems.

These smart lighting products typically require frequent adjustment, remote control, and even automatic brightness regulation based on ambient light, placing higher demands on the reliability, durability, and safety of connectors. Traditional connection methods are increasingly revealing limitations in these emerging application scenarios: issues such as easy wear, complex installation, and high maintenance costs are becoming apparent.

02 Small Components, Big Impact: The Critical Value of Connectors in Smart Lighting

In smart lighting systems, though small, connectors undertake multiple critical missions.

Ensuring Stable Signal Transmission

Smart lighting products rely on stable signal transmission for dimming, color adjustment, and remote control. The quality of connectors directly affects the stability and precision of signal transmission. Inferior connectors can cause issues like light flickering and control failure.

Simplifying Installation and Maintenance

TE Connectivity's modular releasable pluggable connector is a stackable interconnect product suitable for wire-to-LED board connections within luminaires. This pluggable feature enables simple and quick installation, and its various color configurations help with efficient identification and assembly.

Enhancing Product Durability

Smart lighting products often need to operate continuously for long periods. The durability of connectors directly affects the entire product's lifespan. For example, some connectors specifically designed for LED lighting can withstand temperatures up to 125°C, ensuring reliability in high-temperature applications like headlights.

03 New Trends in Connector Technology: Innovative Solutions for Smart Lighting Challenges

To meet the new demands of smart lighting, connector technology continues to innovate and evolve.

Contactless Connection Technology

STMicroelectronics' millimeter-wave contactless connector ST60 represents a revolutionary advancement in connection technology. This technology uses the 60GHz millimeter-wave frequency band to transmit signals, featuring ultra-high bandwidth, ultra-low power consumption, short-distance, point-to-point transmission, and is a physical transmission chip that requires no protocols.

This technology is particularly suitable for LED smart product applications as it solves problems associated with traditional cable connections, such as cumbersome installation and high labor and time costs, while improving connection stability.

Integrated Smart Connectivity Solutions

TE Connectivity's LUMAWISE Endurance S connector system is an innovative product consisting of standardized interface connections that comply with the "Zhaga Book 18 standard." This design allows users to create luminaires with sockets, enabling easy removal and replacement of compatible sensing and communication modules.

Sensing and communication modules typically provide sensory input to LED drivers and communicate with other luminaires in the network, which is crucial for smart lighting systems.

Innovative Designs for Simplified Installation

To address the specific needs of LED lighting applications, connector manufacturers have introduced various innovative products that simplify installation.

TE Connectivity's CoolSplice connector series uses Insulation Displacement Technology (IDT), eliminating the need to pre-remove wire insulation, saving significant time and costs. These connectors are simple to use: just insert the wire into the connector and press the button to secure the wire.

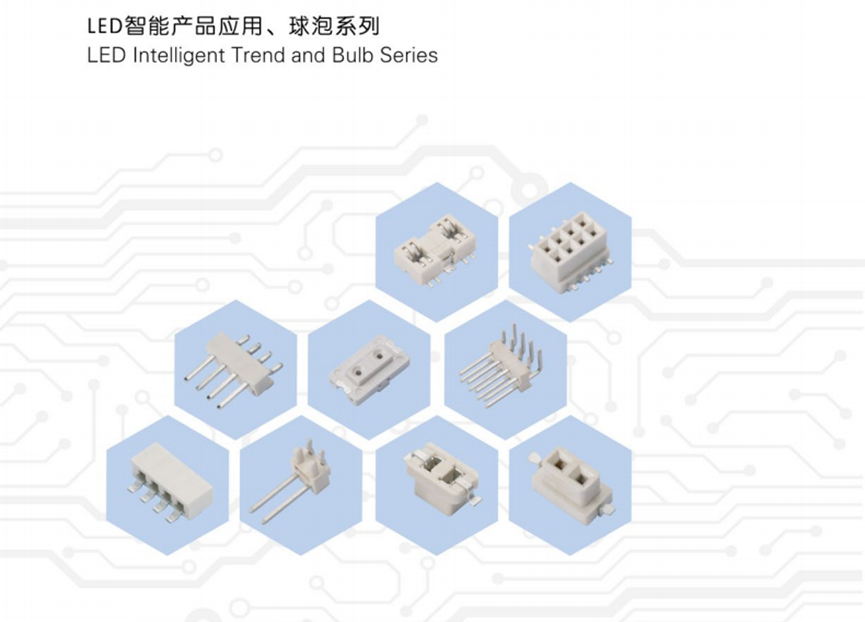

04 Application Cases of Connectors in Specific LED Smart Products

Smart Bulbs

In smart bulbs, space constraints are extremely strict. Panasonic Corporation developed a "board-to-wire connector" with a height of only 3.4mm, one of the thinnest connectors in the industry. This slim connector has minimal impact on the LED's light emission angle, enabling easy production of smaller, thinner LED light modules.

Outdoor Smart Lighting

Outdoor smart lighting products need to withstand harsh environmental conditions. TE Connectivity's CoolSplice connectors provide IPX5, IPX7, and IPX8 (2 hours, 1m underwater) rated joints, enabling waterproof solutions. This reliability is crucial for outdoor smart lighting products, ensuring long-term stable operation.

Smart Control Cabinet Lighting

For LED lighting inside control cabinets, the convenience and safety of connectors are particularly important. WAGO's WINSTA® plug-in connector system is used for Rittal control cabinet luminaires, making connections effortless.

These luminaires not only provide high-quality lighting but also bring great convenience to control equipment and mechanical engineering applications, with simple assembly and quick, error-free installation.

05 Future Outlook: How Connector Technology Will Shape the Future of Smart Lighting

As smart lighting technology continues to develop, connector technology will also continue to evolve. We can anticipate the following development trends:

Wireless and Integrated

Contactless connection technology will see broader application. This technology can not only reduce wear issues of physical connectors but also bring greater flexibility to product design, such as achieving fully enclosed LED display modules with better outdoor waterproof characteristics.

Standardization and Modularization

The establishment of industry standards will promote the compatibility and interchangeability of smart lighting products. Organizations like the Zhaga Consortium are promoting the standardization of LED luminaire components. TE Connectivity's LUMAWISE Endurance S connector system, developed in collaboration with the Zhaga Consortium, is a typical representative of this trend.

Intelligence and Multifunctionality

Future connectors will no longer be simple physical connection components but intelligent modules integrating sensing, communication, and control functions. For example, TE Connectivity's LUMAWISE Endurance S modules not only provide connection functions but can also install various sensors and communication modules, greatly expanding the application scenarios of smart lighting.

The era of smart lighting has arrived, and innovations in connector technology are providing a solid foundation for this transformation. From basic circuit connections to supporting smart function implementation, from simple physical interfaces to integrated smart modules, the development of connector technology continues to expand the possibilities of smart lighting products.

For connector manufacturing enterprises, only by embracing technological innovation as the spear and ecological collaboration as the shield can they build core competitiveness amid the trends of intelligence, integration, and standardization, securing a leading position in the rapidly growing smart lighting market.

Connector Product Recommendations:

| Product Category | Part Number | Product Image |

| Quick Insert Connector | L021 | |

| L024 | ||

| L045 | ||

| L066K | ||

| L079 |

| Product Category | Part Number | Product Image |

| Led Bulb Connector | L017 | |

| L044AFV | ||

| L055AFV | ||

| L1501AFV | ||

| L2004AFV |

| Product Category | Part Number | Product Image |

| T8/T5 Tube Connector | L010A Y | |

| L015 | ||

| L059 | ||

| L2001 | ||

| L023 |

| Product Category | Part Number | Product Image |

| Other Connector | L008 | |

| L018B-E | ||

| L020A-Y | ||

| L002L002Y | ||

| L019L019B |