2025 International Microwave Symposium Unveils Technological Frontiers, as the Global Connector Market Moves Toward a $100 Billion Scale

As the global electronic information industry continues to develop rapidly, connectors—indispensable core basic components in electronic devices—are embracing unprecedented development opportunities and a wave of technological innovation. The latest RF/microwave interconnection solutions showcased at the 2025 International Microwave Symposium (IMS 2025), coupled with the sustained growth of global connector market data, reveal the industry’s technological evolution path and market prospects.

01 Global Connector Market Continues to Expand, China’s Position Grows Increasingly Prominent

According to statistics from Bishop & Associates, the global connector market size has grown from USD 60.1 billion in 2017 to USD 96 billion in 2023, showing a steady growth trend. The Chinese market has performed particularly impressively, with its market share rising from 23.10% in 2011 to 32.03% in 2021. It is estimated that by 2026, the size of China's connector market will reach USD 31.5 billion.

This growth is driven by the rapid development and overall transformation and upgrading of multiple sectors, including communications, automotive, rail transit, and consumer electronics. In particular, with the advancement of 5G infrastructure construction and the expansion of data center scales, the replacement demand from the stock upgrade of downstream markets and the incremental demand from new infrastructure have jointly brought development opportunities to the connector industry.

02 Technological Frontiers: High-Frequency & High-Speed Connectors Become the Focus of Innovation

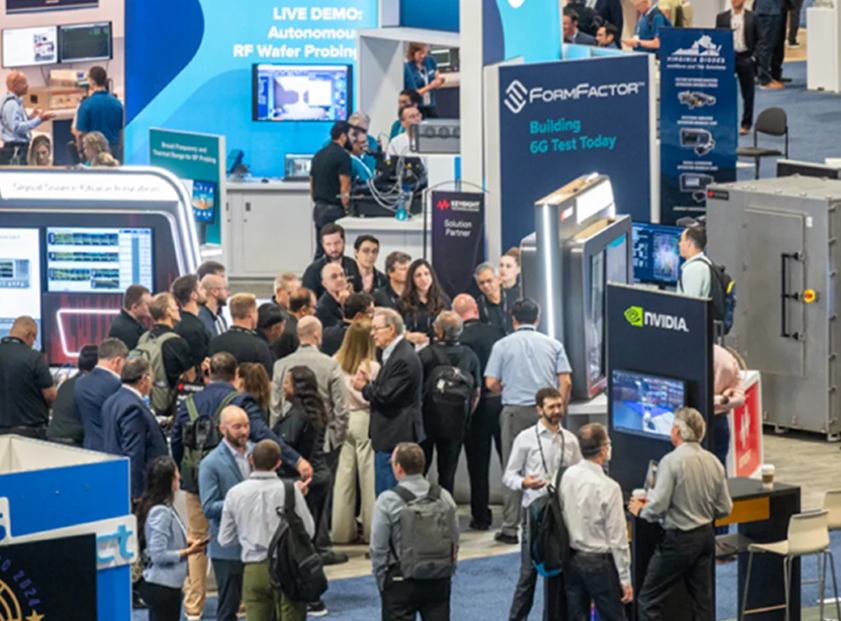

The 2025 International Microwave Symposium (IMS 2025) was held at the Moscone Center in San Francisco from June 15 to 20, attracting over 9,000 participants and more than 500 exhibitors from 55 countries. At the symposium, high-frequency and high-speed connector technologies stood out as highlights:

Anritsu's ME7838G millimeter-wave vector network analyzer system adopts a 0.6 mm interface, with an operating frequency range covering 70 kHz to 220 GHz, meeting the needs of 5G and future 6G frequency bands.

Multiple suppliers (such as Southwest Microwave, SPINNER, etc.) have launched 0.8 mm RF connectors and supporting cables, supporting D-band deployment (for wireless 5G/6G backhaul and radar applications) in the 110-170 GHz frequency range.

Hirose has introduced a new 2.92 mm field-replaceable RF connector suitable for 43.5 GHz.

These technological innovations not only expand the performance boundaries of connectors but also lay the foundation for future 6G applications and higher-speed data transmission.

03 Automotive Electrification Drives Changes in Connector Demand

Technological transformations in the automotive industry are profoundly impacting the connector market. As automotive platforms shift toward electrification and software-defined architectures, the automotive connector market is expected to grow from USD 7.33 billion in 2025 to USD 9.14 billion in 2030, with a compound annual growth rate (CAGR) of 4.51%.

Electrification Drives Demand for High-Voltage Connectors

The transition to 48V and 800V electrical architectures is fundamentally reshaping connector requirements. Aptiv's high-voltage interconnection system supports a voltage range of 400V to 1000V and a current capacity of up to 250A, catering to the industry's shift toward faster charging and improved efficiency. TE Connectivity's AMP+ HVA 280 system features an integrated high-voltage interlock and two-stage floating latches, enhancing safety for applications up to 850V.

ADAS and Autonomous Driving Fuel Growth of High-Speed Connectors

Driven by ADAS (Advanced Driver Assistance Systems) and autonomous driving solutions, demand for high-speed data interconnection is expanding. By 2030, this niche market is expected to grow at a CAGR of 17.8%. Aptiv's H-MTD connector system supports frequencies up to 20 GHz and data rates of 56 Gbit/s, enabling real-time sensor fusion required for Level 3 and Level 4 autonomous functions.

04 Communication Connectors: Driven by 5G and Data Centers

Communication connectors are used in devices such as servers and switches. With the advancement of 5G infrastructure and the expansion of data centers, their market demand continues to grow.

From 2019 to 2021, the global communication connector market size increased from USD 14.269 billion to USD 18.3 billion, with a CAGR of 13.25%. China's communication connector market size grew from USD 6.267 billion to USD 8.1 billion, with a CAGR of 13.91%. According to Bishop & Associates'forecast, the global communication connector market will reach USD 21.5 billion by 2025, while China's market will hit USD 9.5 billion.

05 Material Innovation Coexists with Technological Challenges

The development of connector technology also faces challenges in materials and innovation:

Shortage of High-Performance Resins

The automotive industry's growing reliance on high-temperature and chemical-resistant materials has created supply bottlenecks for specialty resins such as polyphenylene sulfide (PPS) and liquid crystal polymer (LCP). Celanese's Fortron PPS supports operating temperatures up to 240°C and offers excellent chemical resistance, making it indispensable for engine compartments and high-voltage applications. However, power supply constraints limit its availability for automotive use.

Cost Pressure from Copper Price Fluctuations

Driven by supply constraints and surging demand from the renewable energy and electric vehicle (EV) industries, copper prices are rising. EVs require more copper than traditional internal combustion engine (ICE) vehicles—each EV contains approximately 83 kg of copper, compared to 23 kg in traditional vehicles—amplifying the impact of price fluctuations on automotive connector costs.

06 Future Outlook: Innovation and Integration Will Reshape the Industry Landscape

The connector industry is in a critical period of technological transformation, and the following development trends will emerge in the next few years:

Continuous Evolution of High-Frequency & High-Speed Technologies: With the widespread application of 5G millimeter-wave technology and the rapid development of satellite communications, demand for RF connectors above 26.5 GHz is experiencing explosive growth. These high-frequency and high-speed connectors enable faster and more stable data transmission, becoming a key factor driving further upgrades in communication technology.

Miniaturization and High-Density Integration: Represented by the Type-C interface, whose pitch has evolved to 0.4 mm, this places extremely high demands on connector miniaturization and high-density integration. MEMS (Micro-Electro-Mechanical Systems) technology is gradually becoming a new competitive focus in this field, promising to enable more powerful functional integration of connectors in small sizes.

Intelligent Integration: In emerging fields such as the Industrial Internet of Things (IIoT), smart connectors with sensors are gradually emerging. These connectors not only fulfill traditional electrical connection functions but also collect and transmit equipment operation status data in real time, providing strong support for intelligent equipment management and maintenance.

Increased Industry Concentration: As technical requirements rise and market demand grows, the concentration of the connector industry will continue to increase. Suppliers capable of combining semiconductor-level manufacturing precision with software integration support are expected to succeed, as original equipment manufacturers (OEMs) demand fault-tolerant links, wireless updatability, and cybersecurity data paths.

Conclusion

As core components enabling signal and energy transmission between electronic devices, connectors are seeing simultaneous improvements in their technological level and market size. From technological breakthroughs at the International Microwave Symposium to demand changes driven by automotive electrification, and market expansion fueled by 5G and data centers, the connector industry is in an era full of opportunities and challenges.

For connector manufacturers, only by grasping technological development trends, focusing on innovation directions such as high-frequency/high-speed, miniaturization, and intelligence, while optimizing supply chain management to address material cost fluctuations, can they seize opportunities in this industrial transformation and share in the development dividends of the global connector market's $100 billion scale.