Expo Grand Occasion: The "Vanguard" of the Global Semiconductor Industry

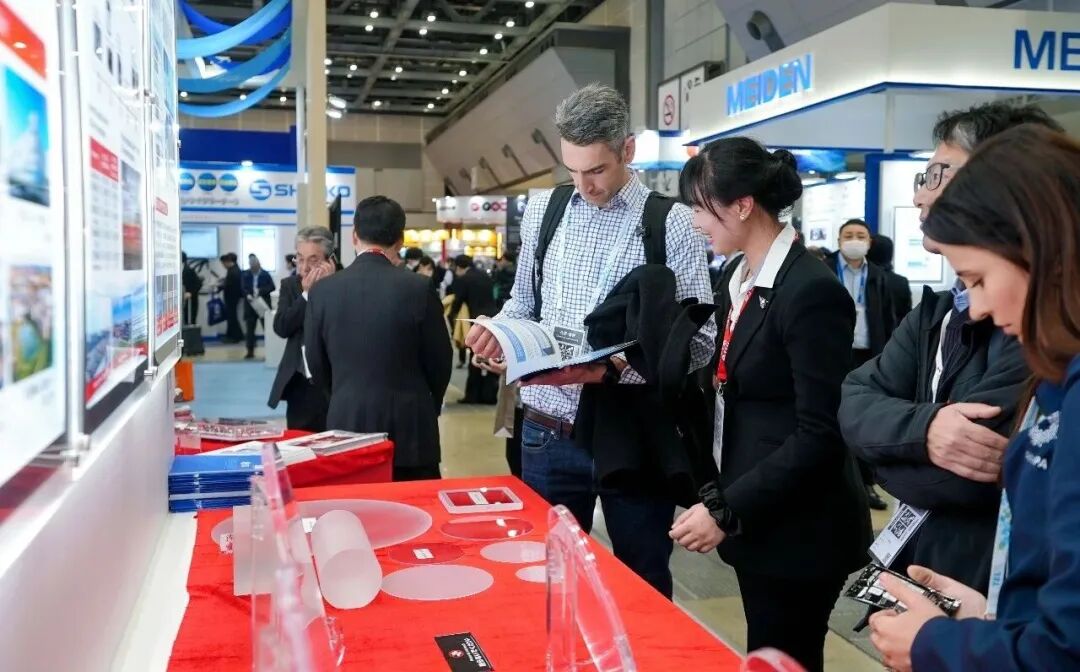

From December 17 to 19, 2025, the 49th SEMICON JAPAN grandly opened at Tokyo Big Sight, attracting 1,216 exhibitors from 35 countries and over 120,000 professional visitors. Centered on "Technological Innovation + Ecosystem Synergy", this year’s expo focused on two core trends: AI and sustainability. It launched two brand-new summits – "AI × Sustainability × Semiconductor (AIS)" and "Metrology & Inspection Summit (MIS)" – comprehensively showcasing the latest technologies and development trends of the global semiconductor industry.

Technological Evolution: From 1.4nm Process to AI-Driven Manufacturing, Connectivity Technology Becomes a Key Pillar

Among the core technological breakthroughs and trends presented at the expo, three development directions are closely linked to basic components such as connectors and wiring harnesses:

1. Process Miniaturization and High-Density Integration

DNP’s global debut of the 1.4nm-class nanoimprint lithography (NIL) template and Rapidus’ progress in 2nm process have become focal points. These advanced processes place unprecedented precision and reliability requirements on the internal connection systems of equipment:

Ultra-high-density signal transmission to ensure accurate delivery of control signals for nanoscale processes

Ultra-stable power connections to meet the power needs of extremely precision equipment

Miniaturized and lightweight design to adapt to space constraints inside equipment

2. The Wave of AI-Driven Smart Manufacturing

The newly launched AIS Summit attracted global giants such as NVIDIA, Intel, and Micron to discuss how AI is reshaping semiconductor manufacturing. The explosive growth of AI servers and data centers poses three major challenges for connectors and wiring harnesses:

High-speed data transmission: Supporting 100Gbps+ transmission rates to ensure real-time, lossless transmission of AI training data

Low-latency signal interaction: Guaranteeing control system response times in the microsecond range to meet precision manufacturing needs

Balance between heat dissipation and reliability: Solving heat dissipation issues in high-density data centers to ensure long-term stable operation

3. Green Manufacturing and Sustainable Development

"The Future of the Semiconductor Supply Chain: Challenges of Sustainable Development" served as the closing session of the expo, emphasizing the importance of equipment energy efficiency and environmental design. This requires connection systems to:

Adopt low-power design to reduce energy consumption

Withstand high temperatures and extreme environments to extend equipment lifespan

Use environmentally friendly materials to minimize environmental impact

Connectors & Wiring Harnesses: The "Neural & Vascular System" of Semiconductor Equipment

Throughout the expo, industry experts have reached a consensus: the reliability and performance of semiconductor manufacturing equipment depend not only on core chips and precision machinery but also on stable and efficient connection systems.

In semiconductor equipment, connectors and wiring harnesses play a critical role as the "neural and vascular system":

Functional Category | Key Role | Technical Requirements |

Power Transmission | Provide stable power for wafer processing equipment and testing instruments | High current-carrying capacity, arc resistance, and operation capability in a wide temperature range (-40℃~125℃) |

Signal Interaction | Ensure accurate data transmission between control systems, sensors, and actuators | Electromagnetic Interference (EMI) resistance, IP67+ protection rating, and signal integrity |

System Interconnection | Connect different equipment modules to build a complete manufacturing system | High density, miniaturization, easy maintenance, and high reliability |

Especially in advanced testing and metrology equipment, the precision of wiring harness systems directly affects the yield of nanoscale processes. On-site at the expo, many equipment manufacturers emphasized that the breakthrough performance of their latest testing equipment is largely attributed to the support of customized precision wiring harness solutions.

JKUN Precision Connectivity: Empowering the Reliable "Neural & Vascular System" of Semiconductor Equipment

As a technical practitioner specializing in electronic interconnection, Wenzhou JKUN Connector Co., Ltd. closely followed this year’s SEMICON JAPAN and deeply recognized that the vigorous development of the semiconductor industry cannot do without the support of precision and reliable connection systems. Our product R&D direction is highly aligned with the core needs of semiconductor equipment:

1. High-Reliability High-Voltage Connectivity Solutions

Targeting the high-power transmission needs of semiconductor equipment, JKUN’s industrial-grade high-voltage connectors adopt special alloy contacts and high-performance insulating materials, featuring:

Excellent high-voltage resistance and arc stability to ensure stable power transmission and avoid equipment downtime due to connection failure

IP67+ protection rating to effectively resist microdust and chemical erosion in semiconductor cleanroom environments

Wide temperature adaptability, enabling long-term stable operation in -40℃~125℃ environments to adapt to temperature differences in different equipment areas

2. High-Speed Anti-Interference Signal Connectivity Technology

Addressing the data transmission needs of AI-driven semiconductor equipment, JKUN’s high-speed signal connectors adopt:

Optimized impedance matching design to support data transmission rates up to 10Gbps and ensure signal integrity

Full shielding structure to effectively suppress electromagnetic interference and protect the "neural signals" of precision testing equipment

High-density layout to save internal equipment space and facilitate equipment miniaturization and integration

3. Customized Wiring Harness Integration Services

JKUN’s professional engineering team can provide full-process wiring harness solutions for semiconductor equipment manufacturers:

Participate in the initial equipment design phase to offer 3D wiring routing planning and EMC simulation

Adopt lightweight and high-temperature resistant materials to reduce system weight while ensuring signal quality

Modular design for easy equipment maintenance and upgrading, reducing long-term operating costs

Leveraging high-reliability design and precision manufacturing experience accumulated in consumer electronics, smart homes, and new energy vehicles, JKUN’s products have obtained multiple international authoritative certifications such as UL, CUL, and CE. With a plug-in lifespan exceeding 2,000 cycles and excellent stability under complex working conditions, our products can seamlessly adapt to the rigorous requirements of semiconductor equipment.

Win-Win Cooperation: Precision Connectivity Empowers the New Future of the Semiconductor Industry

The successful hosting of SEMICON JAPAN 2025 marks that the semiconductor industry has entered a golden age driven by AI and advanced processes. In the wave of development of this trillion-yuan market, close collaboration across the industrial chain is more important than ever.

Wenzhou JKUN Connector Co., Ltd. is not only a professional manufacturer of electronic connectors, LED connectors, and customized wiring harnesses but also a reliable connectivity partner for your semiconductor equipment innovation journey. We will continue to increase R&D investment in key technical areas such as high-speed transmission, high-voltage connectivity, and lightweight design, providing global semiconductor equipment manufacturers with comprehensive connectivity solutions from concept to mass production.

We sincerely invite semiconductor equipment manufacturers and system integrators to conduct technical exchanges with us, exploring how to enhance equipment performance and reliability through precision connectivity technology, and helping the global semiconductor industry move towards a more advanced process and a smarter manufacturing era.

Products Recommendations:

| Product Category | Part Number | Altemative | Product Image |

| Wire-to-Board Connector | |||

| Board-to-Board Connector | B4001 | ||

| Wire-to-Wire Connector | C2002 | ||

| FPC Series | F0503 |