Wiring, also known as flexible circuit board (FPC). It is used to transmit data in the active part and area, such as the hard disk connected to the computer motherboard, the data cable of the optical drive, the data cable connected between the display device and the mobile phone motherboard, etc. Data lines and connected devices are called wiring. The conductor arrangement is mainly divided into two types: round head (r-ffc is directly welded) and flat end (for short-range FFC and Jack). It is especially suitable for data transmission cables between moving parts and main board, board to board, and small electrical equipment. FFC cable will be more and more widely used because its price is better than flexible printed circuit (FPC). In most places where FPC is used, FFC can be used to replace it.

Wiring characteristics

The wire layout is small and lightweight. The original wiring board is used to replace the relatively large wire harness. On the current Ting edge assembly board, wiring is usually the only solution for miniaturization and mobility. Wire placement (sometimes called flexible printed circuit) is to etch copper circuit on polymer substrate or print polymer thick film circuit. On thin, lightweight, compact and complex devices, it can range from single conductive circuit to complex multi-layer three-dimensional assembly. The total weight and volume of wiring are reduced by 70% compared with the traditional circular harness method. In addition, the strength can also be improved by means of reinforcing material or lining.

The movable wire rod can be placed, bent and twisted without damaging the wire rod. It can be packed according to different shapes and special sizes. The only limitation is capacity space. Because it can withstand millions of dynamic bends, the wiring can be well used for the continuous or periodic movement of the internal system as part of the final product function. The thermodynamic stress of solder joint failure on rigid pcb after hundreds of cycles. "There must be a telecommunications number or power supply," said Jenny, eecx product manager. Some products with smaller form factor / package size can benefit from conductor installation.

The electrical and dielectric properties of the wire are very good, "said the president of LT electronics company. Low dielectric constant can make the electrical signal transmit quickly; good thermal properties make the component easy to cool; higher glass transition temperature or melting point makes the component operate normally at higher temperature.

Wiring has high assembly reliability and quality. Wiring reduces the hardware required for internal wiring such as solder joints, trunk lines, backplane lines and cables commonly used in traditional electronic packaging, so that wiring provides higher assembly reliability and quality. As a marketing manager, Ping. Wu shows that this has a high component dislocation rate. Wiring stiffness is low, size is small, and complex multi system Ping. Wu, marketing manager and marketing manager of eecx electronic products department, said that eecx electronic products department is composed of complex multi systems. Because the distribution board components are small, less materials are used. "With the emergence of high-quality engineering technology, thin flexible systems are assembled in only one way, eliminating many human errors usually associated with independent wiring engineering.

What is FFC cabling

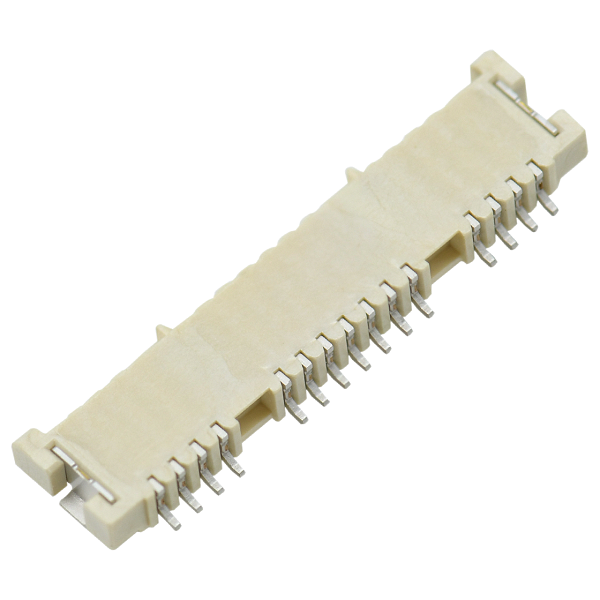

FFC wiring (i.e. flexible flat cable) , the number and spacing of wires can be arbitrarily selected to make the wires more convenient. It greatly reduces the volume of electronic products, reduces production costs and improves production efficiency. It is most suitable for moving parts and mainboard. PCB board is a data transmission cable between PCB board and small electrical equipment. 0.5mm/0.8mm/1.0mm/1.25mm/1.27mm/1.5mm/2.0mm/2.54mm are common specifications.

Line arrangement difference between FFC and FPC

FPC flexible printed circuit printed circuit. In terms of manufacturing, they are formed in different ways:

1. FPC is a flexible circuit board structure with different single-sided, double-sided and multi-layer, which has been chemically corroded by FCCL (i.e. flexible copper foil).

2. The material used by FFC is flat copper foil, and the upper and lower layers are insulating foil film. The appearance of the finished product is simple and the thickness is thicker.