【Technology】Talk about the application of FPC in automobiles (1)

We live in an electrified world where we use all kinds of electronics, cars, cell phones, home appliances, medical devices, robots, etc.,

And what is the most important thing in these electronic products? It is definitely a circuit board(PCB), any electronic product must have a PCB,and with the development of technology, we hope that the electronic products are more flexible, more convenient, smaller size, etc., so our PCB and PCB connection technology is also changing with each passing day....

PCB is a printed circuit board, or called a hard board, also known as a printed circuit board, generally using FR4 as the substrate, can not be bent; so it is generally used in some places that do not need to be bent, the strength is relatively hard, such as computer motherboards, mobile phone motherboards, etc., the general chips are on the motherboard, and the opposite is the flexible board, which is the FPC we talk about today.

The full name of FPC is Flexible Printed Circuit

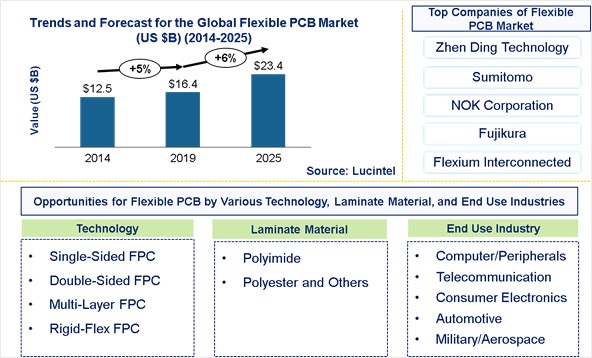

The overall FPC market is expected to reach $23.4 billion by 2025, with a CAGR of 5% to 7% from 2020 to 2025, as lucintel forecasts. The main growth comes from the telecommunications industry, connected equipment, intelligent car electronics, etc., and this is the highest growth rate of the automotive industry, in other words, the era of smart cars will really create a lot of industry ups and downs.

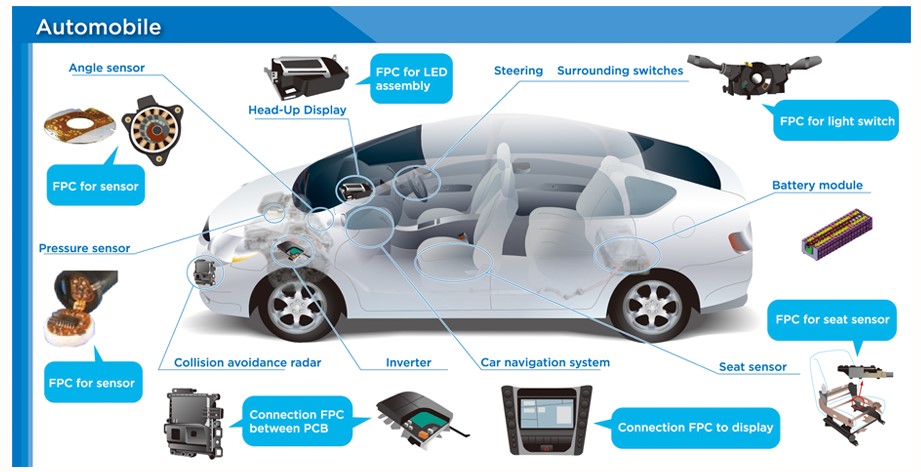

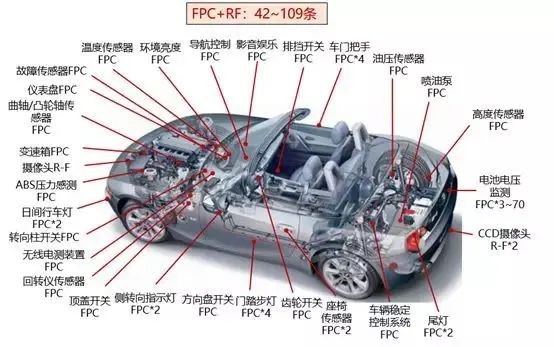

For automobiles, whether it is a fuel vehicle or a smart vehicle, there are a large number of FPC applications, mainly in the automotive electronics sector, automotive electronics is a general term for automotive electronic control devices and automotive electronic control devices. Mainly including engine control system, chassis control system and automotive electronic control system; and from the perspective of structure, space, etc., the future of new energy vehicles will definitely use A LARGE number of FPC instead of wiring harness, will be applied in many parts of the vehicle to achieve, so FPC technology in automotive electronics, especially in intelligent cars is a very important trend, especially in battery BMS, vehicle lighting systems, gate control systems, camera modules, etc.;

Generally, there will be more than 100 FPC applications on an electric vehicle, and I think that this is the application value of FPC and vehicle camera modules in battery BMS, and it is also a key development area

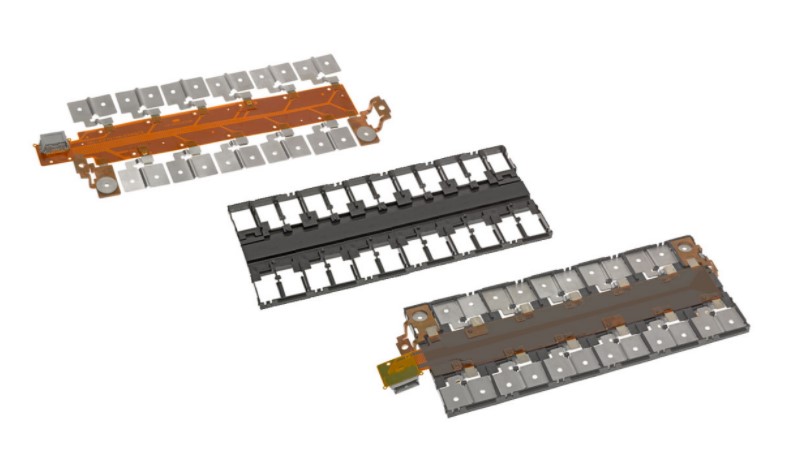

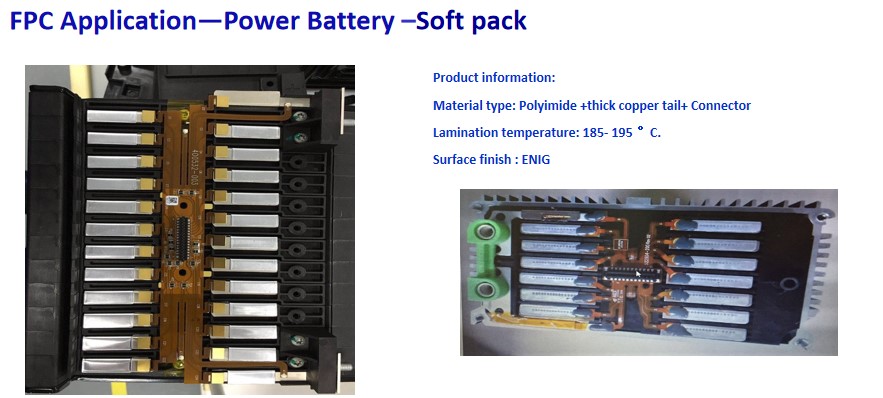

The BMS FPC is applied in the battery, and the cost and space for the battery are two important issues.

As far as the current technology is concerned, the capacity of the battery is basically to the extreme, everyone is asking the structure to be efficient, how to maximize the use of space, and the size of the battery pack is almost fixed, so how many batteries can be loaded in the PACK is actually limited, and the use of FPC to replace the traditional BMS wiring, both to ensure the stability of performance, but also to reduce the risk of breathing to bring the upper cover friction, this is also the mainstream practice of the current family, even in the long run, the motherboard and the circuit from the board can be replaced by chips, The chip can be installed on the FPC, which can maximize the stability of the product, save space and reduce costs (although at present, the cost does not have any advantages), so for any technology iteration, the more it goes to the basic level.

In general, soft pack and hard pack battery is different FPC program, each practice is not the same, including the end of the connector different connection forms have different schemes (crimping, soldering, etc.) The biggest advantage of FPC is its flexibility, in it can evolve with the iterative upgrade of battery control technology, will evolve into many forms, itself is also a customized product, this part of the content I sorted out and kept trying to write another article.

Because FPC is also a product made through lithography technology, it is also a relatively heavy investment industry, there are many suppliers that provide solutions for the vehicle regulation level, basically from the consumer level or other traditional industries, and at present, for battery factories, there are various programs and suppliers, and Amphenol has a large number of successful application experience in this field.