In recent years, surface mount technology (SMT) has developed rapidly and plays an important role in the electronic industry. In addition to the scale effect of fully automated production, SMT has the following technical advantages: components can be mounted on both sides of PCB to achieve high-density assembly; Even the smallest size components can achieve precision mounting, so high-quality PCB components can be produced.

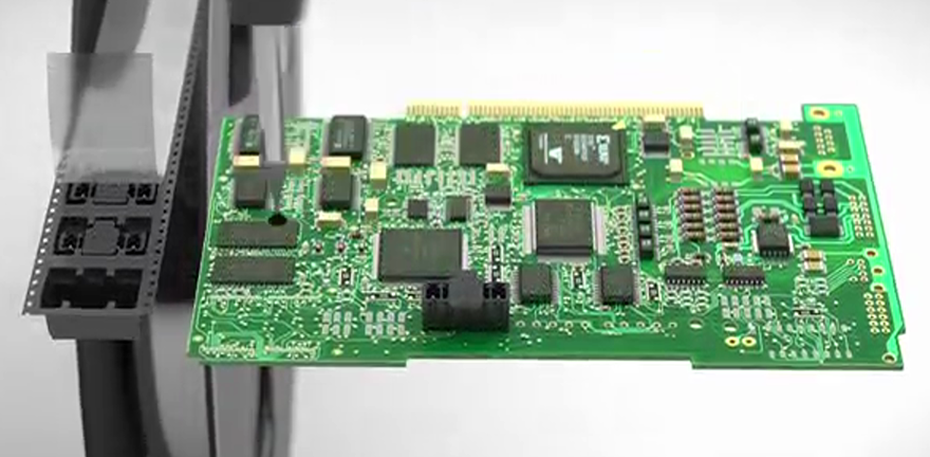

However, in some cases, these advantages are weakened with the reduction of component adhesion on PCB. SMT components are characterized by compact design and easy mounting, which are obviously different from through-hole connectors in size and assembly form. The convenience of operation and the mechanical strength of the connector are also very important factors. The connector is usually the "interface" between the PCB motherboard and the "external components", so sometimes it may encounter considerable external force.

The reliability of components assembled by through-hole technology is much higher than that of corresponding SMT components. Whether it is a strong pull, extrusion or thermal shock, it can withstand it without easy separation from PCB. In terms of cost, SMT components on most PCBs account for about 80%, and the production cost only accounts for 60%; Through hole components account for about 20%, but the production cost accounts for 40%. It can be seen that the production cost of through-hole components is relatively high. For many manufacturing companies, one of the challenges in the future is to develop printed circuit boards using pure SMT process.

Under what circumstances are through-hole reflow soldering techniques used?

1. Traditional wave soldering has many process weaknesses, slow efficiency and difficult process control

2. Simplify processes, automate production and reduce costs

3. Reduce heat treatment, make PCB board and components subject to minimum thermal shock and good welding quality.

4. Flexibility of layout on both sides. Some components need to be arranged on both sides of PCB, and wave soldering can only be carried out on one side

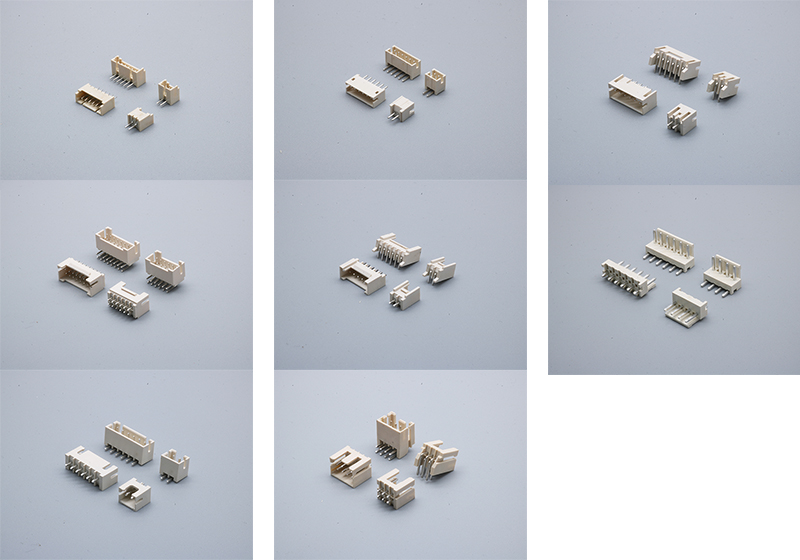

The display of through-hole reflow connectors: