From Field Validation to Industrial Deployment: Electronic Interconnects Enter Performance Upgrade Window

BEIJING, August 17, 2025 — The inaugural World Humanoid Robot Games concluded successfully at Beijing's "Ice Ribbon" from August 14-17, 2025. This technological milestone featured 280 teams from16 countries operating 500+ robots through 487 high-intensity competitions. Beyond demonstrating robotic decision-making and collaborative mobility, the event served as the ultimate stress test for connector performance under extreme conditions:

Unitree's Marathon Robot deployed micro board-to-board connectors achieving10Gbps zero-packet-loss transmission across -40°C to 125°C thermal ranges with continuous vibration, ensuring real-time powertrain coordination.

Dance Robots utilized floating waterproof connectors (IP68-rated) with ±0.5mm stress-compensating technology to resolve joint deformation during high-agility maneuvers.

Deft Manipulators integrated multi-functional micro-connectors (8mm×6mm volume) within 25mm diameter spaces, simultaneously transmitting power, signals, and pneumatic controls to achieve millimeter-precision in pharmaceutical sorting.

I. Technological Breakthroughs: Three Axes Redefining Interconnect Design

1. Miniaturization & High-Density Integration

Beijing Institute for General Artificial Intelligence's manipulator technology requires six micro-connectors per finger, driving industry breakthroughs in 8mm³ volumetric design. Commercialized in medical sorting robots, these connectors reduce error rates below 0.01%.

2. High-Speed Transmission Imperative

To support real-time AI response, connector bandwidth is advancing toward 100Gbps. With motion control latency requirements under 5ms, optimized differential signaling maintains impedance tolerance within ±5% to suppress signal reflection.

3. Extreme Environment Reliability

Industrial inspection robots demand stability in high-EMI/humidity environments. TiG Technology's 360° fully-shielded circular connectors deployed in automotive welding lines achieve 98% equipment utilization. Gold-plated contacts ensure stable contact resistance at 20mΩ.

II. Standardization: Accelerating Industry Harmonization

The Games catalyzed development of the General Specification for Humanoid Robot Connectors, unifying interfaces for joints, sensors, and control systems:

Enhanced Compatibility: 76% of teams(213/280) adopted draft standards, cutting integration time by 40%

Industrial Adoption: Leading Chinese robotics firms initiated standard adaptation, projected to drive >60% industry standardization within three years

"Unified standards reduced R&D cycles by nearly 40%" — University Team Lead Engineer

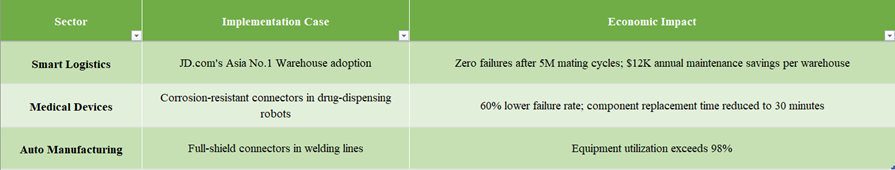

III. Industrial Deployment: Competition Technologies Powering Real-World Applications

IV. Strategic Transformation Pathways

1. High-Speed & Integration

AI computing demands drive 100Gbps+ connector requirements. Power/signal/data tri-integration emerges as the mainstream solution. AVIC Optoelectronics' EVH6E high-current connector reduces wiring nodes by 60% via modular design.

2. Material & Certification Breakthroughs

With 90% high-end LCP insulators imported, domestic development of high-Tg substrates (≥170℃) becomes critical. Medical/automotive certification (AEC-Q200/ISO13485) coverage must increase from <35% to industry-standard levels.

3. Global Supply Chain Realignment

Leading manufacturers accelerate Southeast Asian production: Luxshare Precision's Thailand base cuts Tesla supply chain tariffs by 25%; Recodeal's Mexico factory supplies Cybertruck lines, marking Chinese connectors' entry into core U.S. supply chains.

Industry Outlook

"Connectors evolve from invisible components to intelligent systems' core neural networks"

Humanoid robotics will catalyze a $100B+ connector market expansion:

Near-term (2025-2028):Industrial applications lead with logistics/medical robot connectors growing at 29.4% CAGR

Long-term (2030+): Home service robot proliferation drives demand for sub-6mm³ micro-connectors as joint standards

Strategic Recommendations: Focus on three core competencies

High-voltage coating processes (liquid-cooled ultra-fast charging guns)

EMI-resistant architectures (5G smart factories)

10,000+ mating cycle durability (battery swap systems)

to secure international market access via UL/CE/VDE certification frameworks.

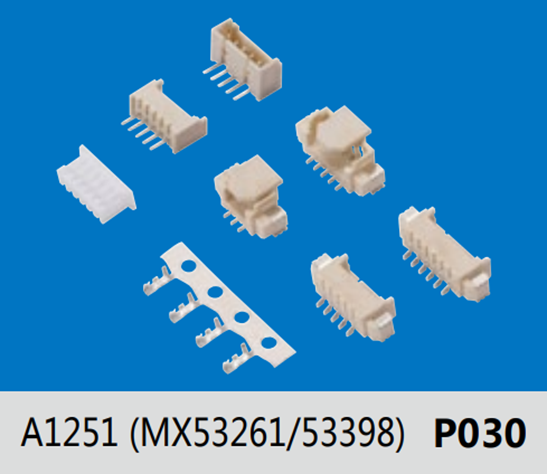

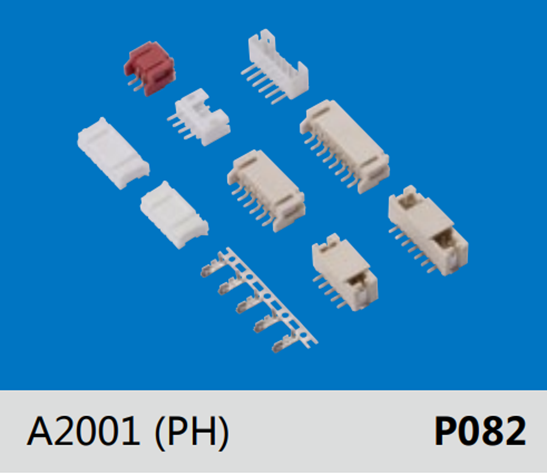

Robotic Connector Product Recommendations:

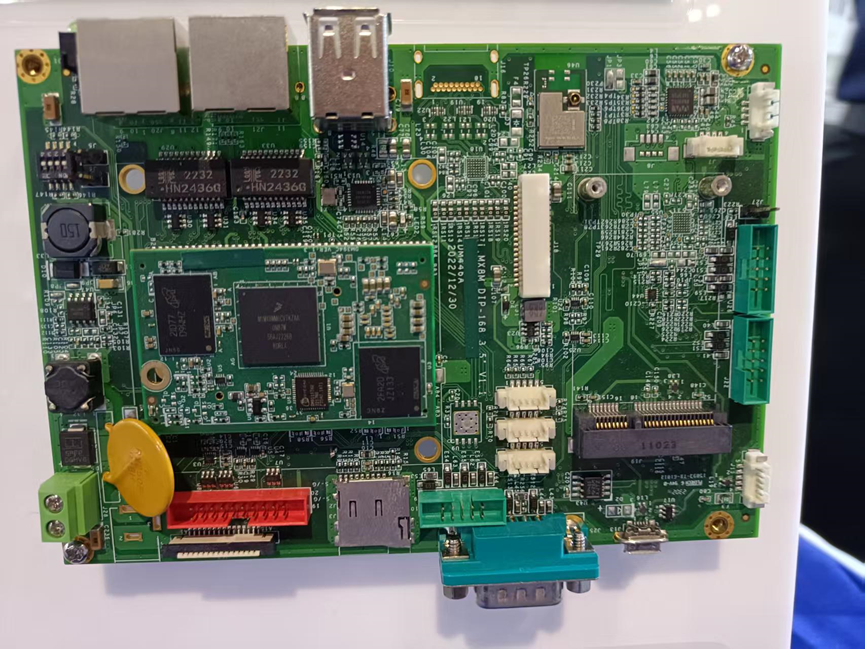

BD2001

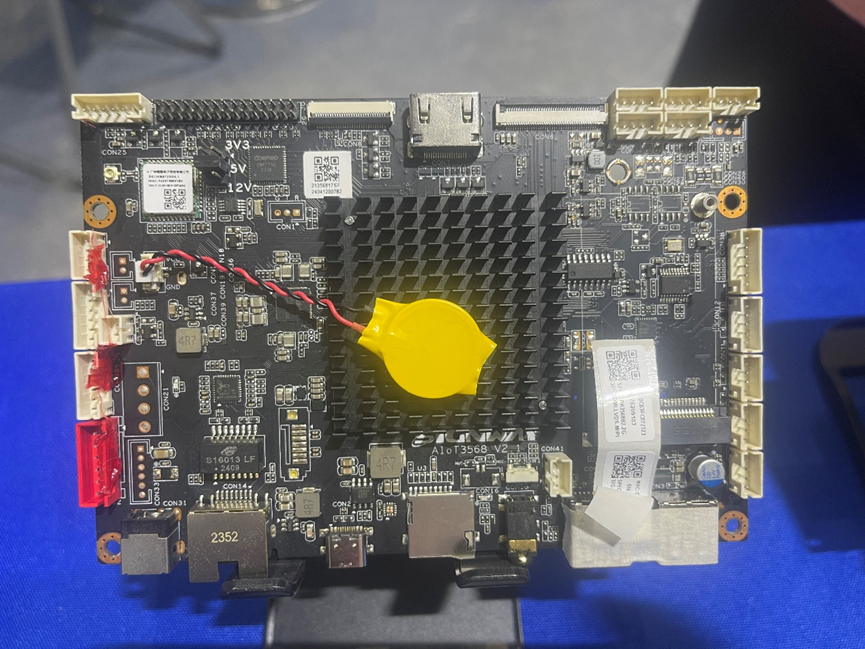

A10013