Exhibition Kickoff: Lithium Battery & Energy Storage Industry Enters a Critical Period of Cost Reduction and Large-Scale Development

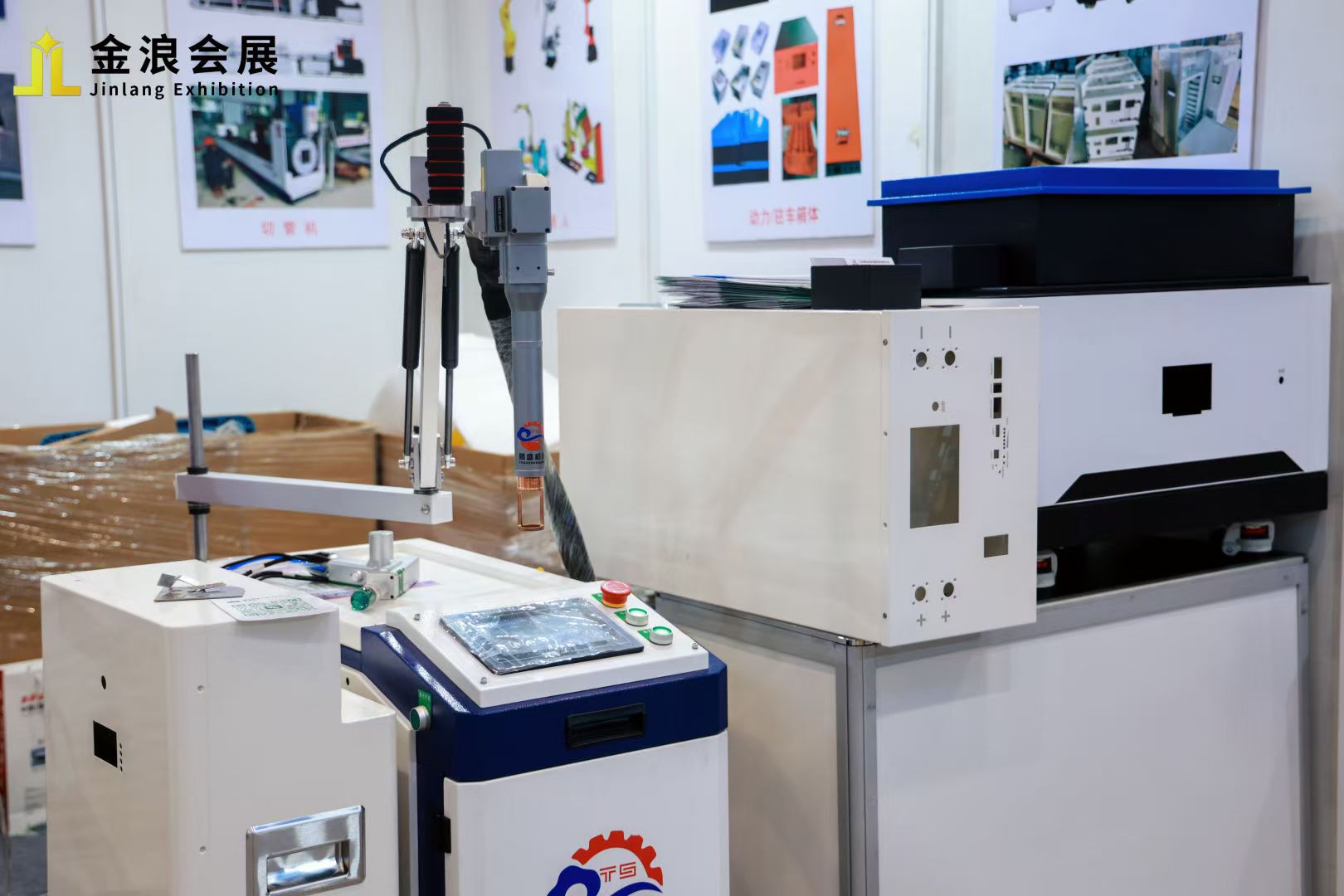

From December 19 to 21, 2025, the 22nd China (International) Lithium Battery & Energy Storage Technology Exhibition successfully concluded at the Xuzhou Huaihai International Expo Center. With the core theme of "New Opportunities · New Products · Core Future", the exhibition leveraged Xuzhou's regional and industrial chain advantages as the "central city of the Huaihai Economic Zone", gathering nearly 300 powerful enterprises from home and abroad. It attracted a large number of industry elites, experts, scholars, and professional buyers, creating an innovative feast covering the entire industrial chain of lithium battery materials, production equipment, power batteries, and energy storage systems.

Amid the accelerated global energy transition, the lithium battery and energy storage industry has moved from the "critical period of technological breakthrough" to the "key stage of cost reduction, efficiency improvement, and large-scale application". At the exhibition, cutting-edge achievements such as 3,000-cycle automotive-grade lithium iron phosphate batteries, integrated solar-storage-charging systems, and intelligent lithium battery chargers were displayed in concentration. The industry focus has clearly shifted from "whether technological implementation is possible" to "how to achieve cost reduction and large-scale development through full-chain optimization". Data shows that efficient business matching during the exhibition led to the signing of multiple cooperation agreements, and the "golden booths" for the next Nanjing exhibition achieved a pre-booking rate of over 25% on the first day—fully demonstrating the industry's firm confidence in future development and indicating that the lithium battery energy storage sector is ushering in a trillion-yuan market blue ocean.

|

|

|

Core Trend: Connectivity Technology Becomes a Core Pillar for Reliable Operation of Lithium Battery Energy Storage Equipment

Throughout the exhibition, whether it is the high-safety operation requirements of power batteries, the long-cycle stability demands of energy storage systems, or the complex working condition adaptation of integrated solar-storage-charging equipment, all rely on the technical support of core basic components. Among these, connectors and wiring harnesses, as the "neural and vascular system" of lithium battery energy storage equipment, directly determine the equipment's power transmission efficiency, signal control accuracy, safety and stability, and service life—becoming one of the key links for industrial cost reduction and efficiency improvement.

Combined with the technical trends and market demands presented at the exhibition, the core requirements for connection systems in the lithium battery energy storage field are concentrated in three aspects:

High-Reliability Power Transmission:During the charging and discharging of power batteries and energy conversion of energy storage systems, they need to withstand high-current and high-voltage impacts. Connectors are required to have excellent high-voltage resistance and arc resistance, while adapting to a wide temperature range of -40℃~125℃ to avoid potential safety hazards caused by connection failure;

Precise Signal Interaction: The Battery Management System (BMS) is the "brain" of lithium battery equipment. The signal transmission between BMS, battery cells, sensors, and actuators must be real-time and lossless. This requires connectors to have strong Electromagnetic Interference (EMI) resistance to ensure the accuracy of state of charge (SOC) estimation, temperature monitoring, and other data;

Lightweight and Integration: To improve the endurance and energy storage density of energy storage equipment while reducing overall manufacturing costs, connectors need to evolve toward miniaturization, high density, and lightweight. Wiring harnesses, on the other hand, need to optimize layout and reduce material waste through modular integrated design.

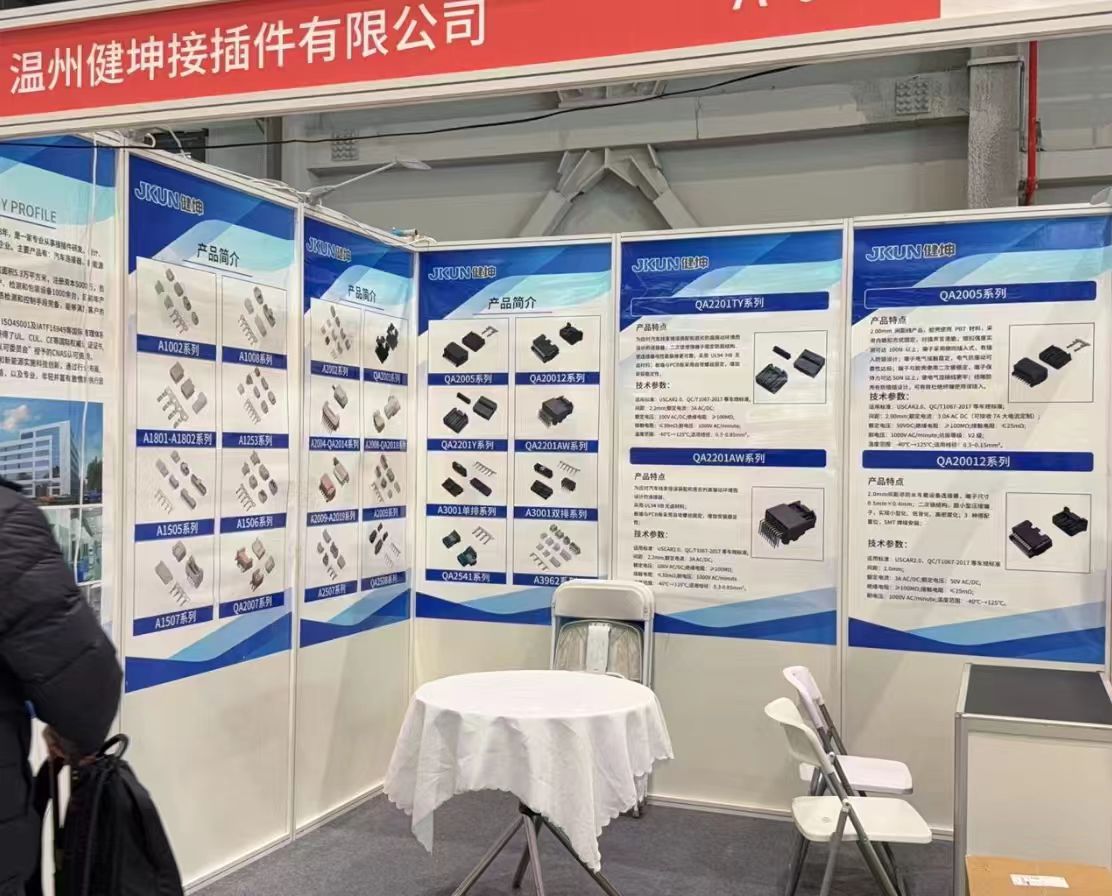

JKUN's Exhibition Debut: Empowering the Upgrade of Lithium Battery Energy Storage Industry with Precision Connectivity

As a professional manufacturer in the electronic interconnection field, Wenzhou JKUN Connector Co., Ltd. made a grand appearance at the exhibition with core connectivity solutions tailored for the lithium battery energy storage sector. With products and technologies that accurately match industry needs, JKUN became one of the highlights of the exhibition, attracting a large number of professional visitors such as lithium battery manufacturers, energy storage system integrators, and charging pile enterprises to stop and consult at the JKUN booth for in-depth discussions.

At this exhibition, JKUN focused on displaying three core product systems, accurately addressing the key pain points of the lithium battery energy storage industry:

1. High-Reliability High-Voltage Connectors: Building a Solid Line of Defense for Power Transmission Safety

Targeting the high-voltage and high-current power transmission needs of lithium battery equipment, JKUN's industrial-grade high-voltage connectors adopt special alloy contacts and high-performance insulating materials, featuring excellent high-voltage resistance, arc stability, and low contact resistance. The products have passed strict vibration, impact, and weather resistance tests, and can easily adapt to the usage needs of lithium battery energy storage equipment in complex environments such as outdoor and vehicle-mounted scenarios. They provide stable and reliable "energy arteries" for core equipment such as power battery packs, Power Conversion Systems (PCS), and charging piles.

|

|

|

2. Anti-Interference Signal Connectors: Safeguarding the Core of Precise Control

Specifically designed for signal transmission scenarios such as Battery Management Systems (BMS), JKUN's high-speed signal connectors adopt a full shielding structure and optimized impedance matching design, which can effectively suppress electromagnetic interference and ensure signal integrity between BMS and various components. At the same time, the products have excellent plug-in stability with a plug-in lifespan exceeding 2,000 cycles, which can long-term ensure the accurate transmission of key data such as temperature, voltage, and current, providing core support for the safe operation of lithium battery equipment.

3. Customized Wiring Harness Integration Solutions: Assisting in Cost Reduction and Efficiency Improvement

Leveraging rich customization experience, JKUN provides full-process wiring harness solutions for lithium battery energy storage equipment manufacturers. The engineering team can deeply participate in the customer's early R&D process, and provide 3D wiring routing planning, Electromagnetic Compatibility (EMC) simulation, and lightweight material selection services based on the equipment structure layout. Through modular integrated design, scattered wiring harnesses are integrated and optimized, which not only reduces material usage and overall weight but also improves equipment assembly efficiency and lowers later maintenance costs—perfectly adapting to diverse application scenarios such as integrated solar-storage-charging and mobile energy storage.

With high-reliability design and precision manufacturing experience accumulated in consumer electronics, smart homes, and new energy vehicles, JKUN's products have obtained multiple international authoritative certifications such as UL, CUL, and CE. Core performance indicators have reached the advanced level of the industry, enabling seamless adaptation to the rigorous requirements of lithium battery energy storage equipment and providing solid connectivity support for industrial cost reduction and large-scale development.

Win-Win Cooperation: Jointly Exploring the New Blue Ocean of the New Energy Industry

The successful conclusion of the 22nd China (International) Lithium Battery & Energy Storage Technology Exhibition not only demonstrated the vigorous development vitality of the industry but also built a high-energy platform for collaborative innovation across the industrial chain. Currently, the lithium battery energy storage industry is in a golden period of large-scale development, and close cooperation between upstream and downstream of the industrial chain is crucial.

As one of the exhibitors, Wenzhou JKUN Connector Co., Ltd. deeply grasps the pulse of industrial development. We will continue to focus on connectivity technology innovation in the lithium battery energy storage field, increase R&D investment in key technical areas such as high-voltage transmission, anti-interference, and lightweight design, and continuously optimize product solutions.

We sincerely invite global manufacturers, system integrators, and other partners in the lithium battery energy storage field to deepen exchanges and cooperation with us. With JKUN's precise customized services, reliable product quality, and profound technical accumulation, we will jointly tackle the challenges of industrial cost reduction and efficiency improvement, inject strong momentum into the global new energy transition, and join hands to explore the new blue ocean of the lithium battery energy storage industry!