From October 21 to 23, 2025, the Motion + Power Technology Expo 2025 was successfully held at Cobo Center Detroit, USA. As an authoritative event in the power and transmission sector, this expo focused on three core themes: "New Energy & Energy Conservation", "Smart Manufacturing", and "Digital & Automation". It gathered over 400 enterprises and more than 18,000 professional visitors from around the world, covering an exhibition area of 20,000 square meters. The expo fully showcased cutting-edge achievements in gear manufacturing, electric drive technology, and intelligent automation solutions.

Expo Focus: Innovation and Application Expansion of Intelligent Transmission Technology

1. Intelligent Elements Deeply Integrated into Transmission Systems

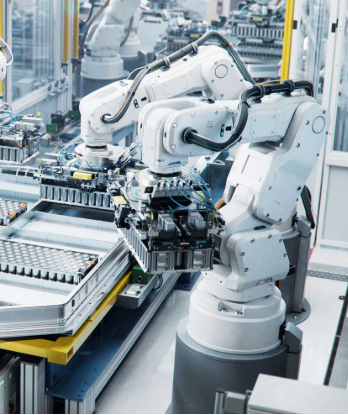

At the expo, enterprises like Klingelnberg demonstrated intelligent gear manufacturing technology integrated with sensing functions. By embedding sensors and software control systems, they realized real-time monitoring and intelligent regulation of the transmission process.

Leading domestic enterprises such as Hiwin Technologies and Global Drive also exhibited innovative products applied in drive systems for industrial robots and motion control.

2. Convenient Design and Extended Lifespan Become Competitive Focuses

Transmission components with quick-installation and quick-disassembly features were highlights of the expo, significantly reducing the time cost and operational difficulty of equipment maintenance.

Meanwhile, the new generation of transmission components, through optimized material processes and structural design, has significantly extended their actual service life cycle on production lines.

Industry Trends: Synergistic Evolution of Connectors and Transmission Technology

1. New Energy Vehicles Drive Growth in Demand for High-Voltage Connectors

As electric vehicles adopt 800V high-voltage architectures, voltage resistance, current-carrying capacity, and reliability of high-voltage connectors have become core competitive factors.

A single new energy vehicle requires 600-1000 connectors, which is 2-3 times that of traditional fuel vehicles. Moreover, the value of high-voltage connectors for new energy vehicles is more than 3 times higher than that for fuel vehicles.

2. Intelligent Applications Drive Upgrades of High-Speed Connectors

L2+ autonomous driving vehicles need to be equipped with more than 20 sensors, and the usage of high-speed connectors per vehicle has surged by over 50% compared with traditional models.

In power transmission systems, intelligent connectors must ensure high-speed and reliable signal transmission. For example, Aptiv’s H-MTD connector system supports frequencies up to 20 GHz and data rates of 56 Gbit/s.

3. Industrial Automation Spurs Demand for High-Reliability Connections

In application scenarios such as industrial robots and AGV robots, connectors need to have high flexibility and bending resistance.

Leading wire harness manufacturers in the industry have developed robot wire harnesses with a bending life of up to 8 million cycles, meeting the high-frequency movement needs of industrial robots.

Strategic Layout and Product Advantages

1. Following Industry Trends to Improve Product Portfolio

High-voltage connector series: Developed higher-voltage high-voltage connectors for new energy vehicle electric drive systems, using new high-temperature and high-voltage resistant insulating materials.

High-speed data connectors: Provide high-speed data transmission solutions for intelligent transmission systems, supporting real-time transmission of sensor data and accurate delivery of control signals.

Specialized connectors for industrial robots: Developed specialized connectors with high vibration resistance and impact resistance, ensuring reliable connection during frequent movements.

2. Leveraging Technical Advantages to Support Transmission System Innovation

Precision manufacturing capabilities: Adopt advanced production equipment and process control technology to ensure high precision and consistency of connector products.

Strict quality control: Implement full-process quality monitoring from raw materials to finished products, ensuring products meet industry standards and customer requirements.

Customized development capabilities: Possess flexible product development and customization capabilities, providing targeted connection solutions based on customers' specific needs.

Future Outlook: Joining Hands to Create a New Future for Intelligent Transmission

With the rapid development of emerging industries such as AI, IoT, and Industry 4.0, power transmission technology is ushering in a new wave of innovation. In the future, power transmission systems will focus more on efficiency, intelligence, and integration, placing higher requirements on connectors.

Adhering to the business philosophy of "Quality First, Customer-Centric", JKUN will continue to improve product quality and technical capabilities, providing higher-quality connector products and solutions for global customers.

Products Recommendations:

| Product Category | Part Number | Altemative | Product Image |

| Automotive Connector | |||

| Electronic Connector | A10013 | ||

| BD2002 | |||

| C2502 | |||

| F0509AWVN |